- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Description

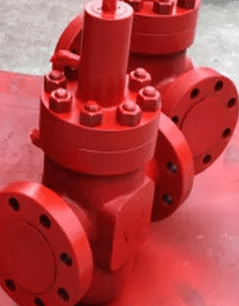

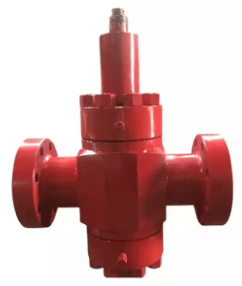

Slab Gate Valve

It provides mechanical and tight sealing when there is high pressure in the system. The high-performance gate also performs through corrosive and abrasive environments. It works best for industries providing the most severe and demanding services. It is used for manufacturing Christmas tree equipment, wellheads, water services, and pipelines.

Two spring-loaded, pressure-energized, non-elastomeric lip seals between each seat and body are useful in low pressure and also in protecting against the inclusion of particle contaminants into the body cavity and seal areas. Slab Gate Valve is also used for extreme sour and subsea applications. These valves can withhold a wide range of pressures, temperatures, and fluids used in manifolds and wellhead services.

Features-

- Metal-to-metal sealing, wedge

- Bi-directional sealing

- Back seat with conical seal surface against stem allows stem seal replacement under pressure.

- The seat faces are outside the flow stream and therefore protected from the erosive action of the flow

- Simple and reliable gate and seat designs

- Easy closing and sealing without excessive torque.

Industries-

- Oil and Gas Industry

- Water service

- Pipeline Industry

- Petroleum