- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Description

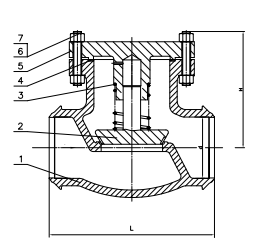

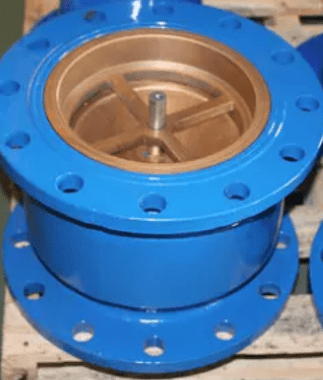

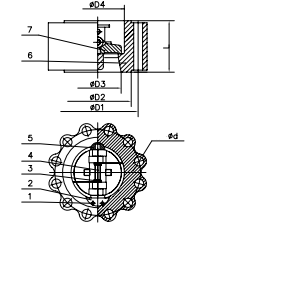

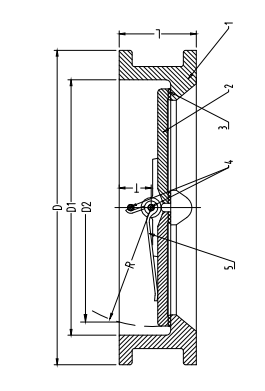

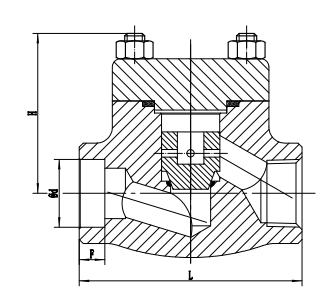

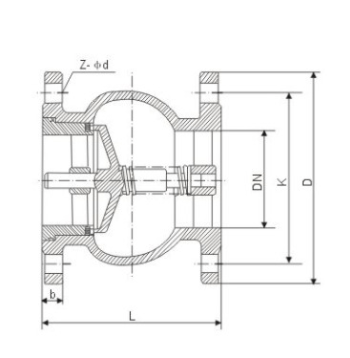

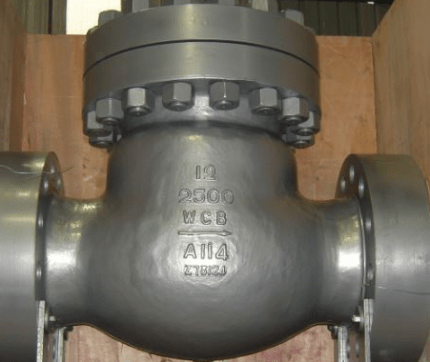

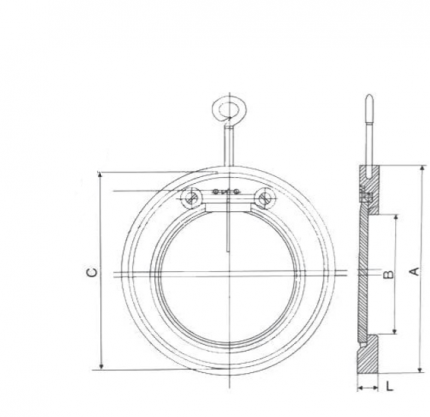

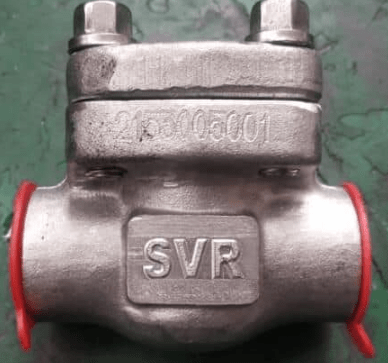

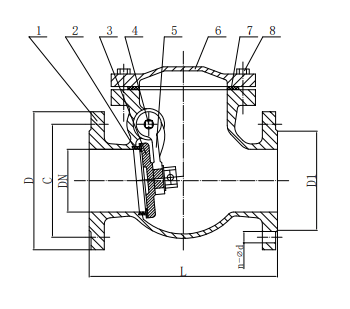

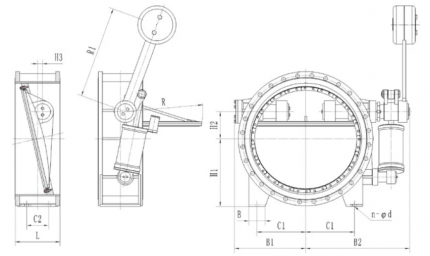

Lift Check Valve

A lift check valve is a type of non-return valve that allows fluid to flow in one direction but prevents it from flowing in the opposite direction. It operates by using a ball or disc that is lifted off its seat by the forward flow of fluid, allowing the fluid to pass through. When the flow of fluid stops or reverses, the ball or disc falls back onto its seat, preventing the fluid from flowing in the opposite direction. These valves are commonly used in plumbing, irrigation, and industrial systems to maintain the desired flow direction of fluids.

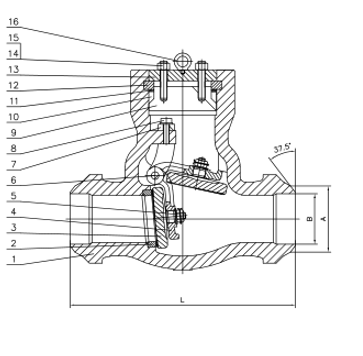

Parts

- Body

- Disc or Ball

- Seat

- Hinge

- Spring

- Inlet and Outlet ports

- Bonnet

- Handle or Lever

[expander_maker id=”1″ more=”Read more” less=”Read less”]

Advantages

- The lift check valve ensures that fluid flows in only one direction, preventing backflow and protecting equipment from damage.

- Lift check valves are relatively simple to install and can be easily integrated into existing systems.

- These valves have few moving parts, which means that they require minimal maintenance.

- They are typically made from durable materials such as cast iron, stainless steel, and bronze, which makes them long-lasting.

- Lift check valves can be used in a wide range of applications, including plumbing, irrigation, and industrial systems.

- They are relatively inexpensive and can be easily replaced if they fail.

- They can be found in a variety of sizes to accommodate different flow rates and pressure requirements.

- They ensure the proper flow of fluid which can reduce the energy consumption.

Industries which use them

- Oil and Gas Industry

- Power Generation plants

- Chemical Industry

- Marine Industry

- Mining Industry

- Pharmaceutical Industry

Applications

- Lift check valves are often used to protect pumps from damage caused by backflow. They allow fluid to flow in one direction and prevent it from flowing in the opposite direction, ensuring that the pump is only exposed to fluid flowing in the correct direction.

- They are used to protect pipelines and other equipment from backflow. They prevent the flow of fluid in the opposite direction and protect against damage caused by reverse flow.

- Lift check valves are used in water supply systems to prevent backflow and protect the water supply from contamination.

- They are used in industrial process systems to control the flow of fluids and gases and protect equipment from damage caused by reverse flow.

- They are used in fire protection systems to prevent backflow and ensure that water flows in the correct direction, providing adequate protection against fire.

- They are used in boiler feed systems to prevent backflow and protect boilers from damage caused by reverse flow.

[/expander_maker]