- Control Valve

- Pneumatic Control Valve

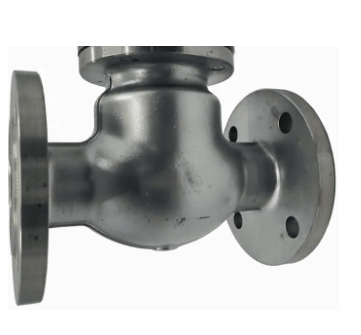

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

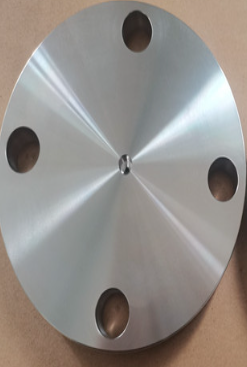

Description

These flanges have stub ends with a lap joint ring flange attached over them. The stub ends are butt welded and the lap joint ring flange is aligned with the mating ring. Lap joint flange uses stub ends when an expensive piping system is used.

A lap joint flange can hold little pressure but more than a slip-on flange. It is very similar to a slip-on flange except it is flat across the face and has a radius machined at the bore. Lap joint flange is therefore used in low-pressure and non-critical applications.

Using lap joint flanges might save costs when the piping is made of expensive materials. By using a lap joint flange, the wetted materials would consist of the materials and the flange would be carbon steel. Since the flange doesn’t ever come in contact with the process fluid, it would not be affected by the fluids.

Advantages:

- Because of the stud ends used in the lap joint flange, we can decide on the pipeline material compatible with the fluid flowing through it. With this, you can use affordable and desirable materials for flange which will not come in contact with fluid flowing through the system.

- You can realign and rotate the flange so that there is a proper connection of the flange with other piping components.

- In heavy corrosion conditions, only stud parts must be removed using the lap joint flange. This can save the costs of removing the backing flange.

Class- 150,300,400,600,900,1500,2500

Ranges of Names:

- Back Up flanges

- Loose Ring flanges

- Loose Hubbed flanges

- Van Stone flanges