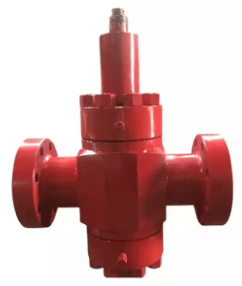

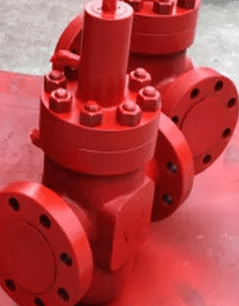

API 6A Swing Check Valve

Shipping

Hurry and get discounts up to 20% Read more

API 6A Swing Check Valve

Soft Edge collection

Shipping

No account yet?

Create an Account