- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

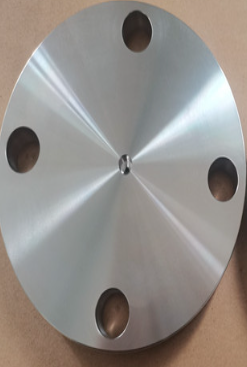

Description

Blind flanges are usually used for blocking pipes and closing the path. These flanges will completely stop the flow of the material running through the passage. They are ideal for blocking pipes in the piping system, valves, and pressurized containers.

Blind flanges are designed for high-pressure conditions. These flanges are specially designed to terminate the pipe in the piping system. There is no hole in the center of this flange so that fluid doesn’t flow through the carnage and can also be used as the rod access point on drain systems.

They are often known as the blank flange as they are used to blank off the ends of the pipe, valves, and pressure opening vessel. Since the maximum stresses in a blind flange are bending stresses at the center, have to be higher than in other types of flanges. The blind flange has a simple design. At the same time, it is expensive compared to other flanges.

Advantages:

- Maintain a high resistance to loosening in severe hydraulic service.

- Helps in installation and repair as it provides easy connection.

- They are useful for high pressure, vibrations, and shocks.

Materials:

ASTM A36 Carbon Steel

ASTM A126 Cast Iron Black & Galvanized

ASTM B62 Bronze

ASTM A105 & A105N Forged Carbon Steel

ASTM A182 F11 & F22 Chrome

ASTM A182 F304/304L, F316/316L

ASTM A240 304 & 316 Plate

ASTM A350 LF2

Standards:

ASTM A182 – ASME SA182 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

ASME B16.5 – ‘Pipe Flanges and Flanged Fittings

ASME B16.36 – ‘Orifice Flanges’

ASME B16.47 – ‘Large Diameter Steel Flanges NPS26 Through NPS60’

MSS SP-6 – ‘Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings

American std CL150, CL300, CL600, Japanese standard JIS 10K, JIS 5K, British std PN10, PN16, PN25, SABS 1123 T1000/3, TABLE D, TABLE E.

Ends: FF, RF, RTJ

Size: ½”- 24”