- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

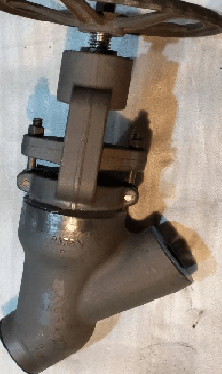

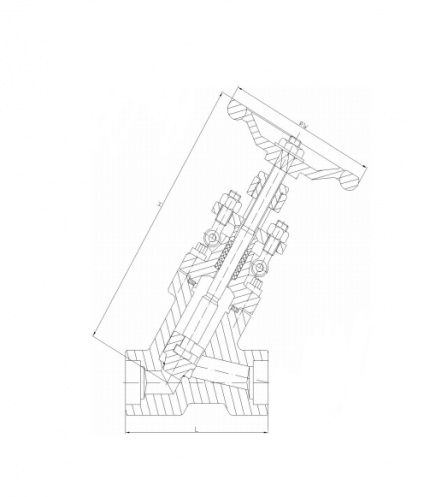

Y Type Globe Valve

Middleeast valve is the foremost Y type globe valve suppliers in Saudi Arabia. Globe valves derive their name from their spherical body shape, which distinguishes them from other valve types. Their design comprises a movable disk-shaped plug, positioned within the valve body. This plug regulates flow by moving up and down in relation to the stationary seat, controlling the passage of fluid through the valve.

Y-Type Globe Valve: Advancing Fluid Management Efficiency

Y-type globe valves represent a specialized variant of traditional globe valves, engineered to optimize fluid management efficiency and mitigate flow restrictions. Understanding their distinctive features and operational advantages elucidates their significance in critical industrial applications.

Meaning and Design:

Y-type globe valves derive their name from the configuration of their internal passageway, resembling the letter “Y.” Unlike standard globe valves, which feature a straight-through flow path, Y-type valves divert the fluid flow at an angle, reducing turbulence and pressure drop. This design minimizes erosion and enhances flow efficiency, making Y-type globe valves particularly well-suited for high-velocity applications.

Working Principle:

The operational principle of Y-type globe valves aligns with that of conventional globe valves, involving the movement of a plug against a seat to regulate flow. However, the unique internal geometry of Y-type valves facilitates smoother fluid passage, optimizing flow characteristics and minimizing energy loss.

Function and Applications:

Y Type globe valves excel in applications where maintaining efficient flow and minimizing pressure drop are critical considerations. Common applications include high-pressure steam systems, boiler feedwater control, and abrasive fluid handling. Their ability to reduce turbulence and erosion makes them indispensable in processes where fluid integrity and system longevity are paramount.

Difference Between Globe Valve and Y-Type Globe Valve:

While both globe valves and Y-type globe valves share the fundamental principle of regulating fluid flow using a plug and seat arrangement, they differ in internal design and flow characteristics. Standard globe valves feature a straight-through flow path, whereas Y-type globe valves divert flow at an angle, reducing turbulence and pressure drop. This distinction makes Y-type globe valves better suited for high-velocity applications where minimizing energy loss and erosion are paramount concerns.

Y type globe valve manufacturers in Saudi Arabia plays integral roles in fluid control systems, each offering unique advantages tailored to specific operational requirements.

Description:

Body material- Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class- 150 – 2500; PN10 – PN 450

Size- DN 10 – DN 1200

Ends- Butt weld, Flanged, threaded, socket weld

Operations- Hand-wheel operated, Pneumatic actuated, Electric actuated, Gear operated