- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

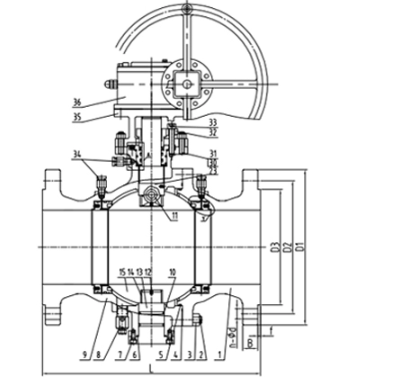

Middleeast is the leading Twin Seal Plug Valve Supplier in Saudi Arabia. It is a type of non-lubricated valve designed for applications requiring a reliable and secure seal. It is primarily used in the oil and gas industry, as well as in pipelines that carry hazardous or high-value fluids. The unique design of the Twin Seal Plug Valve offers a double block-and-bleed function in a single valve body, providing a high level of sealing integrity and operational safety.

Working: it operates by rotating a cylindrical or tapered plug within the valve body. This plug has two sealing surfaces that, when rotated, align with the ports in the valve body to create a tight seal. When the valve is in the closed position, the twin seals (one upstream and one downstream) isolate the fluid completely, preventing any leakage. The space between the two seals can be bled off to ensure no pressure build-up or cross-contamination, enhancing safety.

The primary function of the Twin Seal Plug Valve is to provide a reliable double block-and-bleed capability in a single valve body. It is used to:

1)Isolate sections of a pipeline or system to allow maintenance, testing, or safe shutdown.

2)Ensure that there is no leakage or mixing of fluids between the upstream and downstream sections of the valve.

3)Safely bleed off pressure from the cavity between the seals when the valve is closed, preventing over-pressurization.

Features:

1)Double Block and Bleed (DBB) Functionality: Provides isolation and pressure release in a single valve body, eliminating the need for multiple valves.

2)Non-Lubricated Design: Reduces maintenance requirements and ensures clean operation.

3)Positive Shut-Off: Offers a reliable seal with no leakage, enhancing safety and efficiency.

4)Compact and Lightweight: The design is more compact compared to traditional DBB valve setups, saving space and reducing weight in installations.

5)Low Operating Torque: Easier to operate with less force required, which can extend the life of the valve and associated equipment.

6)Bi-Directional Sealing: Ensures sealing capability from both sides of the valve, offering flexibility in installation and operation.

Benefits:

1)Enhanced Safety: The double block-and-bleed feature provides superior isolation, reducing the risk of accidents or leaks in hazardous environments.

2)Reliable Performance: The design offers long-lasting, maintenance-free operation, reducing downtime and ensuring consistent performance over time.

3)Environmental Protection: By ensuring zero leakage, it minimizes the environmental impact of fluid handling operations, supporting sustainability goals.