- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

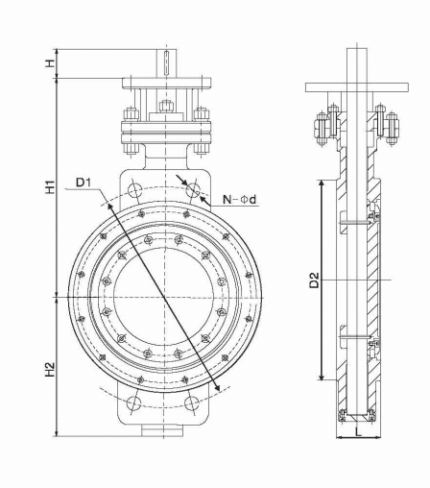

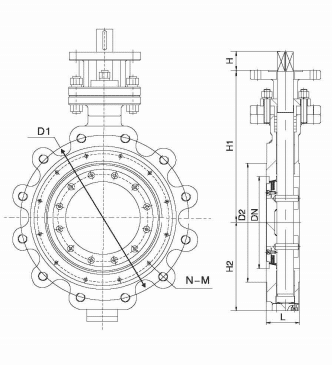

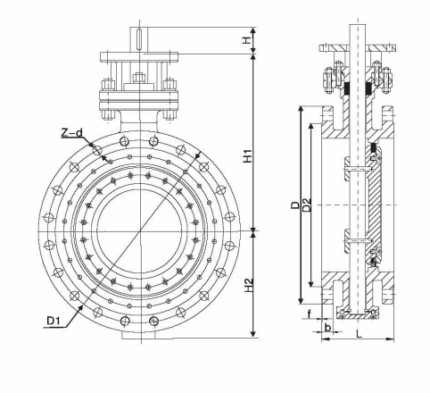

Triple Offset Butterfly Valve Manufacturers in Saudi Arabia: Precise Flow Control

Middleeast valve is famous for Triple Offset Butterfly Valve Manufacturers in Saudi Arabia. It is variant of butterfly valve that is developed to eradicate leakage and minimize friction during operation. This design does not have a conventional butterfly valve in that there are three offsets which ensure the disc does not rub against the seat, suitable for tight close-off in high-temperature and high-pressure situations.

Working Mechanism:

The operation of the valve is based on rotating the disc 90 degrees to open or close the path of flow. The three offsets are:

1)The shaft is offset behind the centerline of the disc.

2)The shaft is offset from the pipe centerline as well.

3)The seating surface is sloped, providing a cone-like geometry for no-friction sealing.

4)This special design provides low wear and a long service life, even in harsh environments.

Benefits:

1)Bubble-tight shut-off with no leakage

2)Low operating torque and low wear

3)High resistance to extreme pressure and temperature

4)Long service life and low maintenance

Industries:

1)Oil & Gas

2)Power Generation

3)Chemical & Petrochemical

4)Marine

5)Pulp & Paper