- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

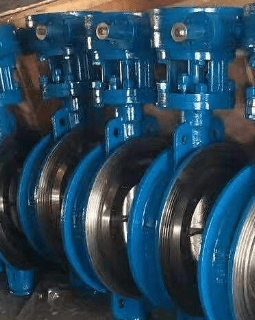

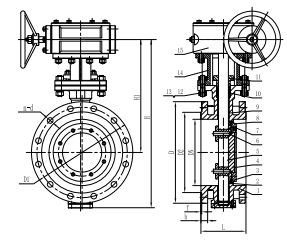

Triple Eccentric Butterfly valve

MiddleEast Valve is the best Triple Eccentric Butterfly valve in Iraq. These valves have an axis that is dynamically positioned as opposed to standard butterfly valves, which have a fixed axis. The valve seat is avoided by the disc during valve opening and only made touch with during valve closure as it revolves. This distinctive design further lowers friction and wear, making the valve appropriate for uses where durable construction and perfect sealing are essential.

Applications requiring excellent performance, such as those involving high-pressure, high-temperature, or abrasive fluids, frequently use these valves. In sectors like oil and gas, petrochemicals, power generation, and water treatment where dependable shut-off and fluid flow control are crucial, these valves are frequently used. They are a popular option for demanding applications due to their sophisticated design, which eliminates the possibility of leakage and enables accurate flow control.

Advantages:

Tight Sealing

Low Torque Requirements

Reduced Wear and Longer Lifespan

High Pressure and Temperature Resistance

Bubble-Tight Shut-Off

Bi-Directional Flow

Applications:

Oil and Gas Industry

Petrochemical Industry

Power Generation

Water Treatment and Distribution

Pulp and Paper Industry

Marine and Shipbuilding

Mining and Minerals Processing

Chemical Industry

Description:

Body Material : Cast iron, Ductile iron, Stainless steel (SS304, SS316, F304, F316, CF8, CF8M, SS316L, SS409L), Carbon steel, Duplex steel.

Class : PN10 to PN100 ANSI 150 to 600

End Connection: Wafer , Lug, Flanged

Size : 2″ to 72”

Operation: Lever, Gear Operated, Electric Actuated, Pneumatic Actuated