- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

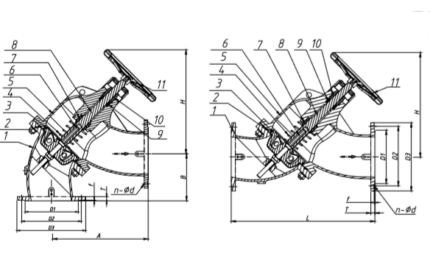

Triple Duty Valve Supplier in Saudi Arabia: All-in-One Solution for Pump System Efficiency

Middleeast valve is one of the greatest Triple Duty Valve Suppliers in UAE. It is a specialized type of control valve used in HVAC (Heating, Ventilation, and Air Conditioning) systems and plumbing systems to perform three important functions within a single valve assembly.

It is a triple duty valve that integrates three functions into one device, i.e., pressure regulation, flow control and isolation. It is a valve intended to remove complexity of system that demand multiple valve for these function.

Components of a Triple Duty Valve:

1)Valve Body: The primary body of the valve that is capable to endure pressure and provide fluid flow control.

2)Actuator: Device utilized to actuate valve, either manual, electric, or pneumatic.

3)Control Mechanism: This control pressure and flow in system, ensuring maximum performance.

4)Seats and Seals: Responsible for maintaining tight seal and leak prevention.

5)Strainer: Remove impurities that might influence operation of valve.

Working Mechanism

Triple duty valve function by bringing together three main function in a single unit. They regulate pressure, control flow, and isolate. Once mounted in a system, valve automatically adapts to changing conditions, regulating flow, pressure, and isolating parts of the system as required. This makes system efficient, saving the system from using several individual valve.

Advantages of Using Triple Duty Valve:

Space and Cost Savings: Avoid use of multiple valves, with the space and cost savings.

Enhanced System Efficiency: Merging function into a single valve enhances system overall performance and reliability.

Low Maintenance: Fewer parts to deal with make maintenance more convenient and economical.

Industries:

1)Steam system

2)Water system

3)Power generation

4)Oil and gas

Description:

Body materials: Cast iron, SS304, SS316, CF8, CF8M, Ductile iron

Size: 2” to 20”

Class: 125 to 300

Nominal Pressure: PN6 to PN25

Ends: Flanged

Operations: Hand wheel operated