- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

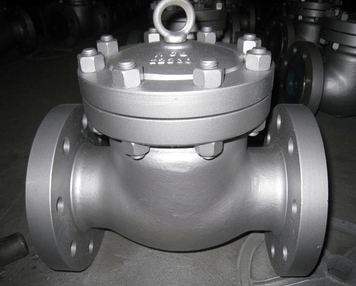

A Titanium Check Valve is a type of valve that allows fluid to flow in one direction while preventing reverse flow. Made from titanium, this valve offers excellent corrosion resistance, making it ideal for demanding applications in harsh environments such as chemical processing, marine industries, and offshore oil and gas operations. Titanium’s light weight and strength ensure durability and efficiency even in extreme conditions.

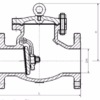

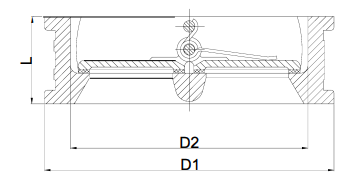

Working of a Titanium Check Valve:

The check valve operates based on differential pressure. When fluid pressure on the inlet side exceeds the pressure on the outlet side, the valve opens to allow flow. Once the outlet pressure becomes higher or the flow reverses, the valve closes automatically, preventing backflow. There are no external controls needed for its operation, as it functions autonomously based on pressure changes in the pipeline.

Function of a Titanium Check Valve:

The primary function of a Titanium Check Valve is to protect equipment and systems from damage caused by reverse flow. This is critical in preventing contamination, equipment wear, or even system failure. It is commonly used in pump systems to maintain pressure, prevent backflow, and ensure operational safety.

Features of a Titanium Check Valve:

1)Corrosion Resistance: Titanium offers exceptional resistance to corrosive environments, particularly in seawater and chemicals.

2)Durability: Titanium’s high strength-to-weight ratio makes the valve lightweight but strong, reducing wear and tear over time.

3)High Temperature Tolerance: Titanium can withstand high temperatures, making it suitable for industrial processes that operate under extreme heat.

4)Non-magnetic: The non-magnetic nature of titanium makes these valves suitable for applications sensitive to magnetic interference.

5)Self-Actuating: The valve operates automatically without manual intervention, relying on fluid pressure to function.

These features make Titanium Check Valves a reliable choice for industries requiring high performance in harsh environments.