- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

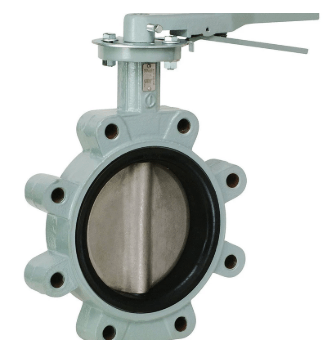

A Titanium Butterfly Valve is a high-performance valve specifically designed for applications where corrosion resistance, lightweight, and durability are critical. Made from titanium, a material known for its excellent strength-to-weight ratio and resistance to corrosive environments, these valves are ideal for industries such as chemical processing, seawater applications, and power generation. They are used to regulate or isolate flow in a piping system by utilizing a rotating disc.

The primary function of a Titanium Butterfly Valve is to control the flow of fluid (liquids or gases) in a pipeline. Unlike traditional valves, the butterfly valve offers quick shutoff capabilities, making it a practical choice for applications requiring fast, efficient operation. The disc in the valve rotates to either block or allow the flow of fluid, depending on the position of the actuator.

Key functions include:

1)Shutoff: Blocking fluid flow entirely.

2)Throttling: Controlling the flow by partially opening the valve.

3)On/Off Control: Quickly allowing full fluid flow or cutting it off.

Working:

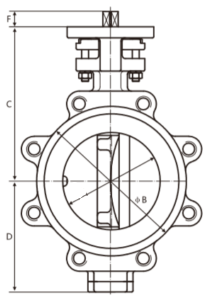

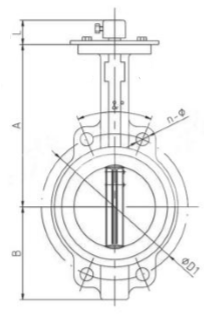

A Titanium Butterfly Valve operates with a quarter-turn mechanism. When the actuator (manual lever or automated device) is turned 90 degrees, it moves the disc, which is mounted on a rod. Depending on the position of the disc:

Open Position: The disc is aligned parallel to the flow, allowing fluid to pass through with minimal resistance.

Closed Position: The disc rotates perpendicular to the flow, blocking the passage of fluid completely.

Because of its simple design, the butterfly valve offers low-pressure drops and fast operation, making it highly efficient in systems where quick and reliable performance is required.

Features:

1)Corrosion Resistance: Titanium offers outstanding resistance to corrosion, particularly in environments involving seawater, chlorides, and various chemicals.

2)Lightweight: Compared to other metals like steel, titanium is much lighter, reducing the overall weight of the valve without compromising its strength.

3)Durability: Titanium Butterfly Valves have long service lives, even in harsh conditions, thanks to the inherent toughness of the material.

4)Compact Design: The slim, compact design allows for installation in tight spaces and makes maintenance more straightforward.

5)High Temperature and Pressure Handling: These valves can operate in high-pressure systems and withstand elevated temperatures without deforming or corroding.

6)Efficient Flow Control: The quarter-turn mechanism allows for rapid open and close functionality, providing precise flow control.

Titanium Butterfly Valves are versatile components suited to industries that demand both strength and resistance to extreme environments. With their lightweight yet durable properties, they are a reliable solution for managing flow in challenging conditions.