- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

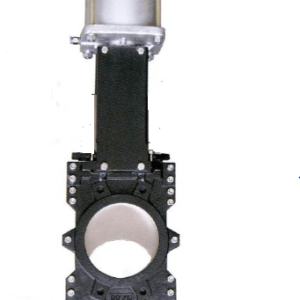

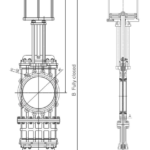

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Middleeast valve is the leading Through Conduit Knife Gate Valve Supplier in Abu Dhabi. It is a specialized type of valve designed primarily to handle and isolate the flow of abrasive or viscous fluids, such as slurries, in pipelines. Unlike traditional gate valves, it features a knife-like gate that slices through the medium, ensuring a tight seal and preventing the buildup of material within the valve body. The “through conduit” design refers to the valve’s ability to provide a full, unrestricted flow path when open, minimizing pressure drop and flow resistance.

The working mechanism of a Through Conduit Knife Gate Valve involves a gate (or blade) that moves perpendicular to the flow of the medium. When the valve is operated, the gate is lowered into the flow path, cutting through any solid particles or debris and sealing against the valve seat. In the open position, the gate is fully retracted into the valve body, creating a full-bore, unobstructed flow passage. This design is particularly effective in minimizing turbulence and pressure drop, making it ideal for handling slurry, pulp, or other abrasive substances.

The primary function of a Through Conduit Knife Gate Valve is to control the flow of media in a pipeline, providing either full flow or complete shutoff. It is specifically engineered to handle challenging media, such as slurries, powders, or highly viscous fluids, without clogging or jamming. The valve’s ability to cut through solids ensures reliable operation in harsh environments, making it suitable for industries like mining, pulp and paper, wastewater treatment, and chemical processing.

Features:

1)Full-Bore Design: Provides an unobstructed flow path, reducing pressure drop and minimizing energy losses.

2)Knife Gate: The sharp-edged gate is designed to cut through solids and prevent material buildup, ensuring a reliable seal.

3)Bidirectional Sealing: Capable of sealing effectively in both flow directions, offering greater flexibility in pipeline design.

Benefits:

1)Reduced Pressure Drop: The through conduit design allows for smooth flow, minimizing pressure losses across the valve.

2)Reliable in Harsh Conditions: Capable of handling abrasive and viscous media without clogging, ensuring uninterrupted operation.

3)Easy Installation and Operation: The simple design allows for easy installation and operation, making it a cost-effective solution for controlling difficult media.