- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

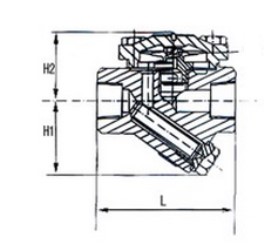

Thermostatic Steam Trap Suppliers in Saudi Arabia: Efficient Steam Control

Middleeast Valve is the topmost Thermostatic steam trap suppliers in Saudi Arabia . It is a device used in steam systems to automatically remove condensate and non-condensable gases (such as air) without allowing steam to escape. It operates based on the temperature difference between the steam and the condensate.

Key Components of Thermostatic Steam Trap:

- (Bellows or Bimetallic) Thermostatic Elements: Expands or contracts with temperature.

- Valve and Seat Assembly: Opening and closing are controlled.

- Body Casing: Generally made of stainless steel or carbon steel

- Air Vent: A quick start-up and air evacuation are facilitated by the air vent facility.

Working Mechanism:

Through the detection of the temperature difference between steam and condensate, thermostatic steam trap function. The element closes the valve as cold condensate flows in. The element expands due to the high temperature of the steam at the trap, closing off the valve to prevent steam leakage.

Advantages of Using Thermostatic Steam Trap:

- Superb energy efficiency

- Accurate temperature control

- Self-contained, no external power needed

- Compact and light construction

- Outstanding ability to expel gases and air

Functions of Thermostatic Steam Trap:

- Condensate is only released when required.

- Air is vented during initiation.

- Stops the loss of live steam

Industries:

- Gas and Oil

- Paper and Textiles

- Systems for HVAC

- Power Plants

Description:

Body Material: Carbon steel, Ductile iron, Stainless steel (SS304, SS316), Cast iron, Forged steel (A105, F11, F22)

Size: 1/2″ to 2″

Nominal Pressure: PN10 to PN250

Class: 150 to 300