- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser Valve

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

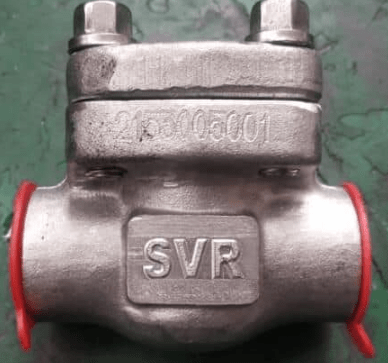

Swing Check Valve

Middleeast valve is famous for Swing check valve supplier in Saudi Arabia. A swing check valve is a type of non-return valve commonly used in pipelines to prevent backflow and ensure unidirectional flow of fluids. The valve gets its name from the swinging action of the disc, which is the main movable component.

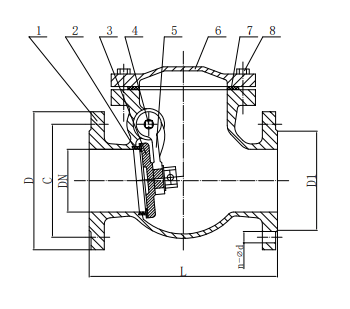

The operation of a swing check valve is relatively straightforward. The valve consists of a hinged disc that swings open and closed inside the valve body. When fluid flows in the desired direction (the forward direction), the pressure of the fluid pushes the disc open, allowing the fluid to pass through. When the flow stops or reverses, gravity and the backflow pressure push the disc back onto the valve seat, effectively sealing the valve and preventing reverse flow.

Working Principle:

Forward Flow Initiation: As fluid enters the valve in the forward direction, the pressure exerted by the fluid forces the disc to swing away from the valve seat.

Disc Movement: The hinged disc moves to an open position, allowing the fluid to flow through the valve with minimal resistance.

Flow Maintenance: As long as the forward flow pressure is maintained, the disc remains in the open position, ensuring a continuous flow of fluid.

Flow Reversal or Stop: When the fluid flow stops or reverses, the reduction or reversal of pressure causes the disc to swing back towards the valve seat.

Sealing: The disc rests against the valve seat, sealing the valve and preventing any backflow.

The primary function of a swing check valve is to permit the flow of fluid in one direction while preventing reverse flow. This is crucial in various applications to protect equipment, prevent contamination, and maintain the integrity of the fluid flow system. Swing check valves are typically used in:

Water Supply Systems: To prevent backflow that could contaminate the clean water supply.

Oil and Gas Pipelines: To avoid reverse flow that could cause pressure surges and potential pipeline damage.

Pump Systems: To protect pumps from damage due to reverse flow and maintain operational efficiency.

Swing check valve supplier in Saudi Arabia are a vital component in fluid flow systems, offering reliable protection against backflow and ensuring the smooth, unidirectional flow of fluids. Their simple design, low maintenance requirements, and versatility make them a preferred choice in many industrial and commercial applications.

Description:

Body materials: Cast steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91] Duplex Steel (F51,F53,5A,4A,6A), Aluminium bronze, cast Iron and ductile Iron

Class: 150 to 2500, PN10 to PN450

Size: 1/2” to 48”

End: Flanged, Socket weld butt weld, wafer,lug, threaded