- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

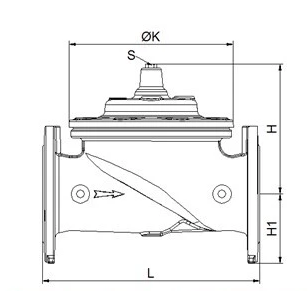

Surge Anticipator Supplier in UAE: Protecting Systems from Water Hammer

Middleeast valve is the most trusted Surge Anticipator valve supplier in UAE. We provide our customers with high quality, durable and cost-effective industrial valves. We supply valves in Saudi Arabia, Syria, Turkey, the United Arab Emirates, and Yemen.

Key Parts of a Surge Anticipator Valve

1)Valve Body – The housing that contains all the components.

2)Pilot Mechanism – A pressure-sensing device to sense pressure surges in the pipeline.

3)Control Valve – It opens or closes based on pressure levels as sensed by the pilot mechanism.

4)Spring and Actuator – Helps the valve in movement according to pressure changes for quick response.

Working Mechanism:

Surge Anticipator valves work by continuously monitoring pipeline pressure. If there is a pressure surge, the pilot mechanism triggers the control valve to open and release excess pressure. The valve closes once the pressure is restored to maintain system integrity. This abolishes pressure surge damage in the way of pipe rupture or pump failure, ensuring smooth and safe operation.

Advantages:

1)Prevents Water Hammer: Reduces the possibility of pressure surging damage.

2)Protects Equipment: Prevents damage to pipelines, pumps, and valves caused by pressure.

3)Increased System Efficiency: Ensures smoothness in fluid flow and reduces maintenance costs.

4)Long-Lasting: Made to withstand high-pressure applications for long-lasting performance.

Industries:

1)Oil & Gas Industry

2)Chemical Industry

3)Petrochemical Industry

4)Power Industry

5)Marine Industry

6)Nuclear Industry

Description:

Material: Ductile iron, Cast iron, WCB

Size: 2 Inch-24 Inch

Class: 150-300

Nominal Pressure: PN10-PN40

Ends: Flanged