- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

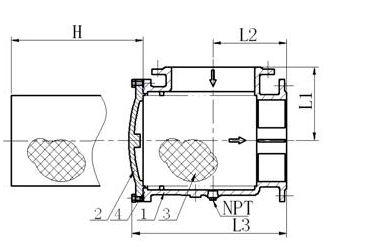

Suction Diffuser Suppliers in UAE: Protecting Pumps with Efficient Flow Conditioning

Middleeast valve is well known for Suction Diffuser Valve Suppliers in UAE. It is a type of valve used in piping systems to improve the flow of fluids, especially in systems where pumps are used to draw fluids from a tank or reservoir. The primary functions are to ensure a smooth and efficient flow of fluid into the pump and to protect the pump from potentially damaging debris.

It is used to smooth fluid flow into pump, compressor or other equipment. It is usually mounted at pump inlet to provide a smooth and consistent flow, avoiding turbulence and cavitation, which can harm equipment.

Components of a Suction Diffuser:

1)Valve Body: The primary unit in which all component reside and can resist pressure.

2)Diffuser: A specifically created component that reduce and redirect fluid flow- allowing for smooth entry into the pump.

3)Strainer: Remove particles and dirt protecting sensitive equipment from damage.

4)Inlet/Outlet Connection: Points at which fluid enters and leaves valve, such that it is designed to join other system component perfectly.

5)Seals: Provide tight, leak free closure for pressure and system integrity purposes.

Working Mechanism:

It functions to guide and slow down fluid flow as it enter into pump or compressor. The diffuser guide fluid into wider area, slowing velocity and turbulence. This also assist in avoiding cavitation, which may happen when fluid flow too rapidly or irregularly and may damage equipment severely.

Advantages of Using Suction Diffuser:

1)Prevents Cavitation: Reduces cavitation risk, increasing pump and compressor lifetime.

2)Improves Flow Efficiency: Provides consistent, smooth flow, enhancing efficiency of fluid system.

3)Protect Equipment: Safeguard pump and other equipment from damage due to turbulent flow.

4)Extended System Longevity: Through elimination of turbulence and promotion of smooth flow, suction diffuser valve help ensure overall system longevity.

Industries:

1)Municipal water systems

2)Fire protection systems

3)Plumbing

Description:

Body Material: – Cast iron, Ductile iron, WCB.

Size:- 2” to 48”

Class:- 150 to 300

Nominal Pressure:- PN6 to PN25

Operation:- Handwheel

End Connection:- Flanged