- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

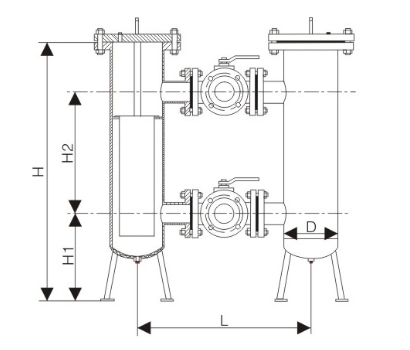

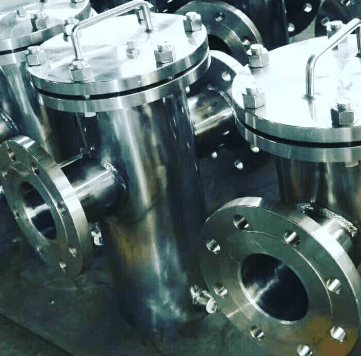

Strainer Suppliers in UAE: Effective Filtration for Clean and Safe Operations

Middleeast valve is the foremost Strainer suppliers in UAE. It is a mechanical device designed to filter out solid particles from a fluid stream, including liquids and gases. It is typically installed in pipelines or process systems to ensure the quality and integrity of the fluid being transported.

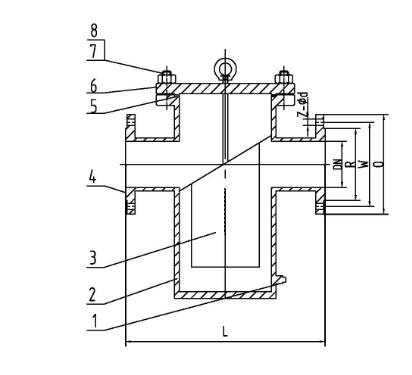

Key Parts of a Strainer:

1)Body: The main casing that houses the internal components and connects to the pipeline.

2)Basket/Screen: The filtering element that captures impurities.

3)Inlet & Outlet: Connections where fluid enters and exits the strainer.

4)Cover: Provides access for maintenance and cleaning.

5)Blow-off Valve (Optional): For cleaning accumulated debris without removing the strainer.

Working Mechanism of Strainer:

As the fluid passes through the strainer, it moves through the mesh or perforated basket. The particle and debris are caught on screen while clean fluid proceed downstream. Occasionally, the strainer is cleaned to remove accumulated debris ensuring maximum performance.

Types:

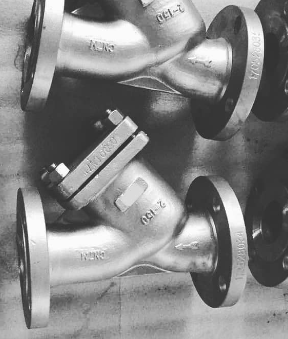

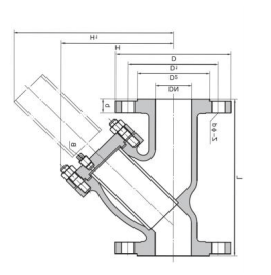

1)Y type Strainer

2)Simple Basket Strainer

3)Duplex Basket Strainer

Industries:

1)Oil & Gas

2)Chemical Processing

3)Water Treatment

4)Power Generation

5)HVAC System

Description:

Material: Bronze, Cast Iron, Cast Carbon Steel, Cast Stainless Steel, Stainless Steel (SS202, SS304, SS316), Forged Brass Body, Ductile Iron, PP, Forged Stainless Steel (F304, F316), Forged Alloy Steel Body.

Class: 150-2500

Nominal Pressure: PN6- PN450

Size: ½” to 24”

Ends: Buttweld, Flanged, Socket weld, Threaded.