- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

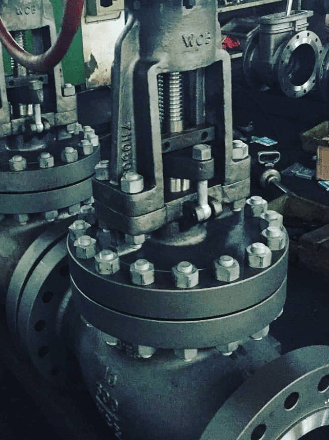

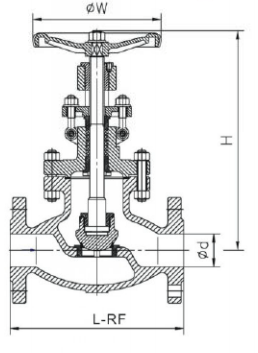

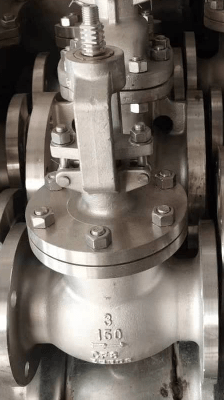

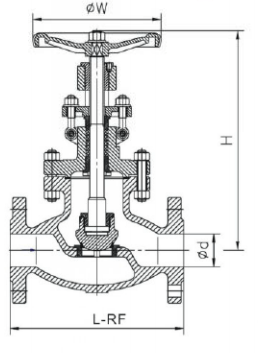

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

A steel globe valve is a type of linear valve used to control the flow of fluid through a piping system. Characterized by its spherical body shape, this valve is designed to provide efficient flow regulation and is commonly made from various types of steel, including carbon steel, stainless steel, and alloy steel. Steel globe valves are known for their durability, resistance to high pressures, and ability to handle a variety of fluids, making them a popular choice in industrial applications.

The operation of a steel globe valve is straightforward yet effective. It consists of a movable disk (or plug) that is positioned inside the valve body, which can be raised or lowered to control fluid flow. Here’s how it works:

1)Open Position: When the valve is fully opened, the disk is raised to allow fluid to flow freely through the valve. This position minimizes the resistance to flow, ensuring optimal performance.

2)Closed Position: When the valve is closed, the disk is lowered to seal against a seat in the valve body. This action prevents any fluid from passing through, effectively shutting off the flow.

3)Flow Control: By partially opening the valve, the disk can be adjusted to control the flow rate. This allows for precise regulation of fluid flow in the system.

4)Directional Flow: Steel globe valves are designed for unidirectional flow, meaning they can only regulate flow in one direction. This feature ensures safe and efficient operation in various applications.

Steel globe valves serve several important functions in a piping system:

1)Flow Regulation: They provide precise control over fluid flow rates, allowing operators to adjust the flow to meet specific process requirements.

2)Isolation: Steel globe valves are often used to isolate sections of a piping system for maintenance or repair. When closed, they prevent fluid from flowing through, ensuring safety during such operations.

3)Throttling: These valves can also be used for throttling, allowing operators to fine-tune the flow and pressure within a system, which is crucial for maintaining optimal operational conditions.

4)Safety: Steel globe valves can be used in critical applications where controlling fluid flow is vital for safety, such as in power plants, chemical processing, and oil and gas facilities.

Steel globe valves come with several key features that enhance their performance and suitability for various applications:

1)Durability: Made from high-quality steel, these valves are resistant to corrosion, wear, and high temperatures, ensuring long-lasting performance in demanding environments.

2)Easy Operation: The design of the globe valve allows for smooth and easy operation, whether manually or with automated systems.

3)High Pressure and Temperature Ratings: Steel globe valves are capable of handling high-pressure and high-temperature applications, making them suitable for industries like oil and gas, power generation, and chemical processing.

4)Leakage Prevention: The design of the valve, including the disk and seat configuration, minimizes the risk of leaks, ensuring safe operation.

5)Maintenance Friendly: Many steel globe valves are designed for easy maintenance, with features like replaceable seats and seals that reduce downtime and operational costs.

Steel globe valves are essential components in fluid control systems, offering reliable performance and versatility across various industries. Their ability to regulate flow, isolate sections of piping, and withstand harsh conditions makes them a popular choice for engineers and operators alike.