- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

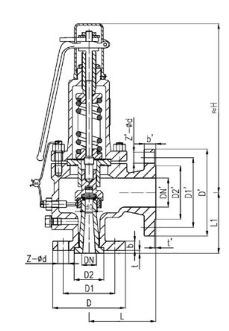

Steam Safety Valve

Middleeast valve is among the top Steam safety valve supplier and manufacturer in Jeddah. We supply to Riyadh, Taif, Damman, and Jubail. A steam safety valve is a device that automatically releases pressure from a steam boiler if the pressure exceeds a safe limit. The valve opens to allow the excess steam to escape, preventing damage to the boiler and other equipment. Safety valves are typically set to open at a specific pressure, and will close again once the pressure drops to a safe level. They are an important safety feature in steam systems and are required by most codes and regulations.

Middleeast valve is the largest Steam safety valve supplier and manufacturer in Jeddah. While manufacturing, we keep in mind the industrial standards and maintain the quality standards of the valves.

Parts

Bonnet

Spring

Disc

Seat

Stem

Lever or Actuator

Inlet and Outlet

Gasket

Bonnet Bolts

Drain Plug

Advantages

The primary advantage of a steam safety valve is that it helps to protect equipment, such as boilers and pipelines, from damage due to overpressure.

These valves are required by most codes and regulations to ensure that steam systems are safe and meet industry standards.

Steam safety valves are designed to open automatically if the pressure exceeds a certain limit, providing a level of protection even if operators are not present.

These valves are relatively simple in construction and are easy to maintain, which can help to keep equipment running smoothly.

They are a cost-effective way to protect equipment from damage, as the cost of a valve is typically much less than the cost of repairing or replacing damaged equipment.

Steam safety valves can prevent unnecessary energy losses by ensuring that steam is not escaping through leaks or overpressure, which can help to save on energy costs.

Steam safety valves are available in a wide range of sizes and designs, making them suitable for use in a variety of applications.

Industries

Power Generation Plants

Chemical and Petrochemical Industry

Pulp and Paper Industry

Textile Industry

Marine Industry

Metal processing Industry

Manufacturing Industry

Applications

Steam safety valves are used in power plants to protect boilers and other equipment from overpressure.

These valves are used in chemical and petrochemical plants to protect equipment such as reactors, distillation columns, and heat exchangers.

These safety valves are used in the pharmaceutical industry to protect equipment such as autoclaves, sterilizers, and distillation units.

Steam safety valves are used in the food and beverage industry to protect equipment such as boilers, pasteurizers, and sterilizers.

These valves are used in the pulp and paper industry to protect equipment such as boilers, digesters, and dryers.

Steam safety valves are used in the textile industry to protect equipment such as boilers, calenders, and dryers.

Steam safety valves are used on marine vessels, such as ships and submarines, to protect boilers, turbines, and other equipment from overpressure.

These valves are used in the metal processing industry to protect equipment such as boilers, heat exchangers, and smelters.

They are used in a wide range of manufacturing industries, including automotive, aerospace, and heavy equipment, to protect boilers, heat exchangers, and other equipment from overpressure.

Steam safety valves are used to protect boilers from overpressure by automatically releasing excess steam.

Steam safety valves are used to relieve pressure in steam systems to prevent damage to equipment and piping.

Steam safety valves are used to protect equipment such as heat exchangers, autoclaves, and distillation columns from overpressure.

These safety valves are used to protect steam traps from overpressure and ensure that they continue to operate correctly.

Steam safety valves are used to control the pressure in steam systems, allowing for more precise and efficient operation of equipment.

These valves are used as a safety shut-off mechanism in case of emergency to protect personnel and equipment.

Steam safety valves are used to regulate the pressure and flow of steam in distribution systems, ensuring that the right amount of steam is delivered to where it is needed.

They are used in steam injection systems to control the pressure and flow of steam, which is used to heat or cool a process.

Steam safety valves are used in steam tracing systems to control the pressure and flow of steam, which is used to keep pipelines and equipment warm.

Steam safety valves are used in steam storage systems to control the pressure and flow of steam, which is used to store energy for later use.

Description-

Available Materials: Cast iron, Ductile Iron, WCB, SS304, SS316, CF8, CF8M, WC6, WCC, LCB, LCC

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: ½” to 40”

Operation: pilot-operated, pneumatic, and electric