- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

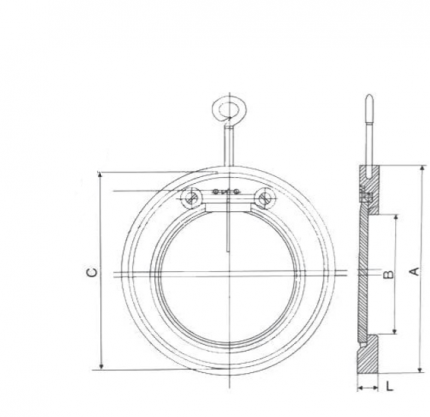

Single Plate Check Valve

Middleeast valve is the leading Single plate check valve manufacturers in Saudi Arabia. A single plate check valve, also known as a swing check valve, is a fundamental component in fluid control systems, ensuring the unidirectional flow of liquids or gases. Its design features a hinged disc, which swings open to allow flow in one direction and promptly closes to prevent backflow, thereby maintaining system efficiency and safety.

The operation of a single plate check valve is straightforward yet crucial. When the fluid or gas flows in the desired direction, the pressure lifts the hinged disc, allowing passage. Once the flow stops or reverses, the weight of the disc, aided by gravity or spring assistance, swiftly closes the valve, preventing backflow and maintaining system efficiency.

Difference between Single Plate Check Valve and Check Valve:

The term “check valve” is an umbrella term encompassing various designs, including the single plate check valve. However, when comparing the single plate check valve to other types of check valves like swing check valves or lift check valves, some key differences emerge:

Design: Single plate check valves feature a hinged disc design, whereas other check valves may utilize different mechanisms such as a lift or ball.

Size and Weight: Single plate check valves tend to be more compact and lightweight compared to some other types of check valves, making them suitable for applications with space constraints.

Response Time: The response time of a single plate check valve to changes in flow direction may vary compared to other designs, influencing its suitability for specific applications.

Installation Orientation: While single plate check valves are typically installed horizontally, other check valve designs may be suitable for vertical or angled orientations depending on their construction.

Middleeast valve is the greatest Single plate check valve manufacturers in Saudi Arabia and its the common purpose of preventing backflow, the specific design features

Description:

Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), DUPLEX AND Super duplex STEEL [ F51, F53,F55 ] Forged Steel A105, A105N, F11, F22, F304, F316, F91] , Alloy20 , Hastelloy ALBR.

Size- ½” – 80”

Class-150 – 2500; PN10 – PN-450

Ends- Threaded, socket weld, butt weld, flanged, lug, wafer.