- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

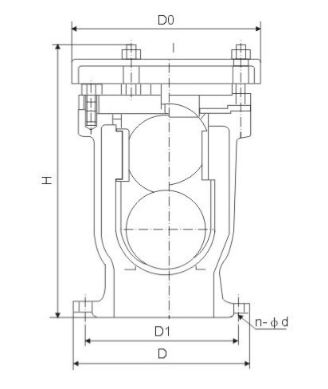

Middleeast valve is well known for Single Orifice Air Valve Supplier in Sharjah. It is a type of valve used in fluid systems to allow air to escape from the pipeline while preventing the fluid from escaping. It is specifically designed to release trapped air that accumulates in pipelines during filling or operation, ensuring that the system operates efficiently without air blockages.

The Single Orifice Air Valve operates by allowing air to vent out from the pipeline when it is under pressure. When the pipeline is being filled, air is displaced and pushed toward the highest points in the system. As the air reaches the valve, it is released through the orifice. Once the air is fully evacuated, the fluid in the pipeline rises, causing the float inside the valve to rise and seal the orifice, preventing any fluid from escaping. During normal operation, the valve remains closed, but it will open automatically to release air if any accumulates during operation.

The primary function of a Single Orifice Air Valve is to:

1)Release Trapped Air: Remove air that accumulates in pipelines, preventing air pockets that can impede fluid flow.

2)Prevent Air Blockages: Ensure that the pipeline remains free of air blockages, which can cause inefficiencies and reduce the system’s overall performance.

3)Maintain Pipeline Efficiency: By removing air, the valve helps maintain the flow efficiency and pressure within the pipeline, ensuring smooth operation.

Features:

1)Compact Design: Typically small and easy to install at high points in the pipeline where air is likely to accumulate.

2)Automatic Operation: Opens automatically to release air and closes to prevent fluid leakage, requiring minimal maintenance.

3)Corrosion Resistance: Constructed from materials that resist corrosion, ensuring a long service life even in harsh environments.

4)High Sensitivity: Responds quickly to the presence of air, ensuring rapid air release to maintain system efficiency.

5)Durable Float Mechanism: The internal float mechanism is designed to reliably seal the orifice after air has been expelled, preventing fluid leakage.

Benefits:

1)Prevents Air-Related Issues: Eliminates air pockets, reducing the risk of air hammer, pressure surges, and flow disruptions.

2)Improves System Efficiency: Ensures that pipelines operate at maximum efficiency by preventing air-related flow restrictions.

3)Reduces Maintenance Costs: Minimizes the need for manual air release and reduces the likelihood of damage caused by air in the system.

4)Enhances Operational Safety: By preventing pressure surges and blockages, the valve contributes to the overall safety and reliability of the pipeline system.

5)Prolongs Equipment Life: Protects pumps, valves, and other equipment from damage caused by air-related issues, extending their operational lifespan.

Single Orifice Air Valve Supplier in Sharjah is a vital component in ensuring the smooth and efficient operation of fluid pipelines, particularly in systems where the presence of air can significantly impact performance. Its simple yet effective design makes it an essential part of modern fluid management systems.