- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

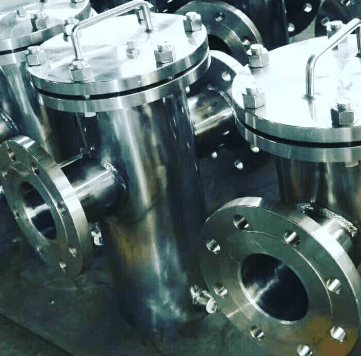

Middleeast Valve is the greatest Simplex Basket Strainer Supplier in Dubai. A Simplex Basket Strainer is a device used in various industrial applications to filter out unwanted solids from liquid flows. It’s designed to protect equipment such as pumps, valves, and pipelines from potential damage caused by debris and impurities. The term “Simplex” refers to the single-basket configuration within the strainer, which is typically sufficient for applications requiring periodic cleaning and maintenance.

The primary function of a Simplex Basket Strainer is to remove particulate matter from liquid streams. This is achieved by directing the flow through a perforated or mesh-lined basket that captures and retains the solids while allowing the clean fluid to pass through. Once the basket becomes filled with debris, it can be removed, cleaned, and reinstalled, ensuring continuous protection for the downstream equipment.

Working:

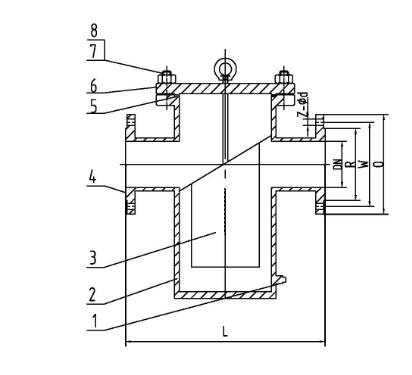

1)Inlet: The unfiltered fluid enters the strainer body through the inlet connection.

2)Filtration: The fluid passes through the strainer basket, which traps and holds the solid particles.

3)Outlet: The cleaned fluid exits the strainer through the outlet connection.

4)Maintenance: When the basket is filled with debris, the system is temporarily shut down to remove the basket for cleaning or replacement. The clean basket is then reinstalled, and the system is brought back online.

Features:

1)Robust Construction: Made from durable materials such as stainless steel, carbon steel, or other alloys to withstand harsh operating conditions.

2)Easy Maintenance: Designed for straightforward removal and cleaning of the strainer basket, minimizing downtime.

3)Variety of Sizes and Configurations: Available in various sizes to accommodate different flow rates and filtration needs.

4)High Filtration Efficiency: Equipped with baskets that offer fine filtration capabilities, ensuring effective removal of contaminants.

5)Compact Design: Space-efficient design suitable for installation in tight spaces.

Benefits:

1)Protection for Equipment: By removing solids from the fluid stream, the strainer helps protect downstream equipment from damage, thereby extending their service life.

2)Improved Process Efficiency: Ensures a clean fluid flow, which can enhance the efficiency and reliability of industrial processes.

3)Reduced Maintenance Costs: Prevents clogging and damage to pumps and valves, reducing the frequency and cost of repairs.

4)Operational Safety: Minimizes the risk of equipment failure and process interruptions, contributing to a safer working environment.

5)Cost-Effective: Simple and durable design makes it a cost-effective solution for filtration needs.

The Simplex Basket Strainer is an essential component in many industrial systems, ensuring smooth and efficient operations by effectively removing contaminants from liquid flows.