- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

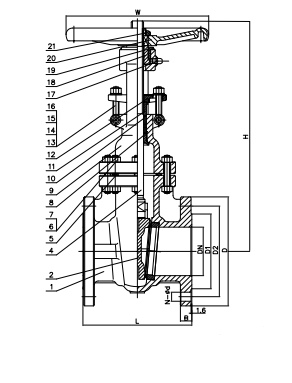

Rising Stem Stainless Steel Gate Valve

Middleeast is a fast-growing and emerging rising stem stainless steel gate valve supplier in Oman. We supply to South Africa, Egypt, Algeria, Saudi Arabia, United Arab Emirates, Iran and Iraq. A rising stem stainless steel gate valve is a type of valve that is commonly used in industrial and commercial piping systems. The valve is made of stainless steel, which makes it resistant to corrosion and suitable for use in harsh environments. The “rising stem” refers to the design of the valve, in which the stem of the valve rises and lowers as the valve is opened and closed. This allows for an easy visual indication of the valve’s position and makes it easy to operate. The valve is used to control the flow of liquids or gases and can be used in a variety of applications, including water treatment, chemical processing, and oil and gas production.

The working principle of a rising stem stainless steel gate valve is based on the movement of a gate or wedge-shaped disc inside the valve body. When the valve is in the closed position, the gate is positioned parallel to the flow of the liquid or gas, blocking the flow through the valve. When the valve is opened, the stem connected to the gate is rotated, raising the gate out of the way of the flow. This allows the liquid or gas to pass through the valve.

The stem of the valve is connected to a hand wheel or other actuator, which is used to rotate the stem and open or close the valve. When the hand wheel is turned clockwise, the stem is rotated, raising the gate, and opening the valve. When the hand wheel is turned counter clockwise, the stem is rotated in the opposite direction, lowering the gate, and closing the valve.

Middleeast is the largest rising stem stainless steel gate valve supplier in Oman. While manufacturing, we keep in mind the industrial standards and maintain the quality standards of the valves.

Advantages

- It is a highly durable material

- Easy to operate

- It can be used in a broad range of application

- It provides a tight shutoff when it is fully closed

Industries

- Water treatment

- Chemical processing

- Oil and gas production

- Power generation

- Marine

- Mining

Parts

- Body

- Gate

- Stem

- Handwheel

- Packing

- Bonnet

- Wedge

- Gland

- Backseat

- bolts

Description

- Available materials: Stainless steel(SS304,SS316,SS316L,CF3M, CF8M,CF8,F316,F316L,904L)

- Size: 1/2″- 64”

- Class: 150 to 2500

- Nominal Pressure: PN10 to PN450

- Operation: Hand Wheel, Gear operated, Electric and Pneumatic Actuated

- Ends: Flanged, Buttweld, Socketweld, Threaded

- Standards: ASME, API6D, API607, DIN, BS, ANSI, AWWA