- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

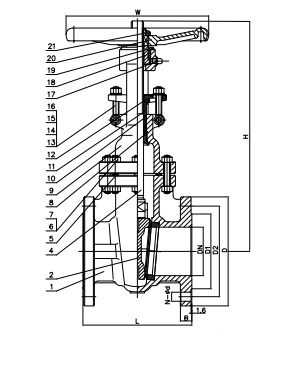

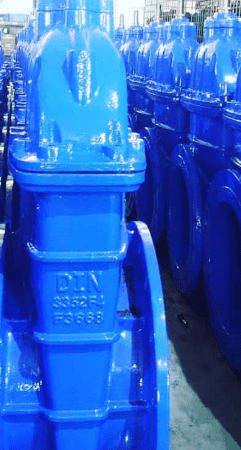

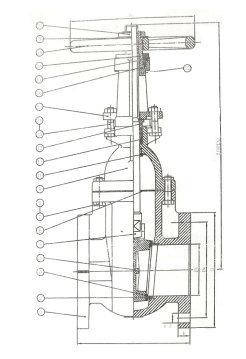

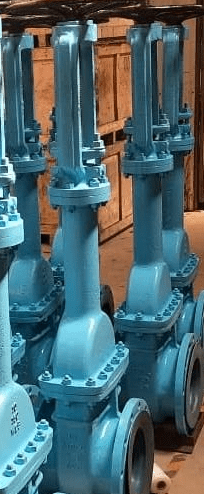

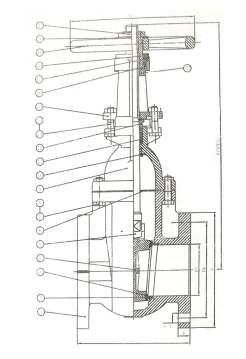

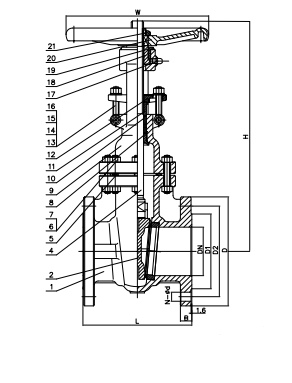

Rising Stem Gate Valve

Middleeast Valve is the well reputated manufacturing company of Rising stem Gate valve in UAE .We supply different types of valves to Dubai , UAE .The gate is the opening and closing portion of the rising stem gate valve, and its movement direction is perpendicular to the fluid direction. The rising stem gate valve can only be opened and closed completely; it cannot be adjusted or throttled. There are two sealing surfaces on the ram. The most commonly used model gate valve’s two sealing surfaces form a wedge. The wedge angle varies depending on the valve parameters, but it is usually 50 degrees. It is 2 ° 52’when the medium temperature is not high.

The wedge gate valve is classified into three types: single gate plate, double gate plate, and elastic gate valve. Parallel gate valves are classified as single gate plate or double gate plate. It is classified into two types based on the thread position of the stem: rising stem gate valves and non-rising stem gate valves.

Advantages of a Rising Stem Gate Valve:

- Fluid resistance is low, and the sealing surface is eroded and eroded by medium.

- The structure is straightforward, the structure length is brief, the manufacturing technology is advanced, and the application range is broad.

- Opening and closing require less effort.

- The medium’s flow direction is not restricted, and it does not disrupt the flow or reduce pressure.

Disadvantages of a Rising Stem Gate Valve:

- The sealing surfaces are easily eroded and abraded, and they are difficult to maintain.

- Because of the large size of the opening, the opening and closing times are lengthy.

- The structure is intricate.

- According to the sealing surface configuration, gate valves are classified as wedge gate valves or parallel gate valves. Wedge gate valves are classified as single gate pole, double gate plate, and elastic gate valves; parallel gate valves are classified as single gate plate and double gate plate. It is classified into two types based on the thread position of the stem: rising stem gate valves and non-rising stem gate valves.

Applications of a Rising Stem Gate Valve:

- Potable water applications

- Shipbuilding

- Wastewater

- Water treatment and distribution systems

Industries that use Rising Stem Gate Valve:

- Chemical Industry

- Mining Industry

- Paper Industry

- Power Industry

- Water treatment

Definition of a Gate Valve:

Gate are used to stop the flow of fluid, a gate valve has a flat closure element that slides into the flow stream. They are one of the most common types of valves, and their primary function is to allow or prevent the flow of liquids.

Gate valves can also be used in harsh environments such as high temperature and high pressure. They are frequently used in:

- Water treatment

- Plants

- Mining

- Offshore applications

A “gate” is a rectangular or circular wedge that is part of a linear motion valve called a gate valve. To open or close a metal gate, it can be raised or lowered. When lifted, the gate opens and allows flow; when dropped, it closes and blocks the channel.

Gate valves are classified as having a rising or non rising stem. Rising stems indicate the position of the valve. A pointer threaded onto the upper end of a nonrising stem valve may be used to indicate valve position. Non-rising stems are frequently used underground or in situations where vertical space is limited.

Industries

Gate valves are used in many industrial applications, including:

- Oil and gas industry

- Manufacturing

- Automotive

- Marine

Description of a Rising Stem Gate Valve:

Middleeast Valve is the well reputated manufacturing company of Rising stem Gate valve in UAE offering an extensive range of valves in numerous sizes, styles and designs.

- Class: PN10 to PN 450; 150 to 2500

- Ends: Buttweld, Flanged, Socketweld, Threaded

- Materials: Cast iron, Cast steel (WCB, WCC, WC6, WC9, LCB, LCC), Ductile iron, SS304, SS316

- Size: 1/2’’to 24’’

- Operations: Electric Actuated, Pneumatic Actuated, Gear Operated, Handwheel Operated.