- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

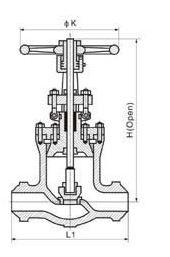

Pressure Seal Globe valve

Middle East valve is the best Pressure Seal Globe valve supplier in Muscat. These valves have a special pressure-sealing system that improves its performance and dependability in harsh environments. The valve has a globe-shaped body with an internal moveable disc or plug that is attached to a stem. The disc travels up or down when the stem rotates, providing for accurate fluid flow control. A tight and dependable seal between the valve body and bonnet is made possible by the pressure seal design, preventing leakage even under demanding operating conditions.

As there is no need for conventional packing glands with this bonnet design, it is ideal for applications where maintaining a tight seal is crucial. Pressure seal globe valves are a popular option in industries where performance and safety are of utmost importance because of their reputation for toughness and ability to tolerate challenging operating circumstances.

Advantages:

High-Pressure Capability

High-Temperature Resistance

Tight Sealing

Precise Flow Control

Durability

Industries:

Power Generation

Oil and Gas

Petrochemical

Chemical Processing

Refining

Industrial Manufacturing

Utility Services

Description:

Body materials: Carbon steel, A105, F304, F316, F304L, F316L, F51, F53, F11, F22.

Class: 150 – 2500.

Size: 1/2”-48”.

Ends: Socket weld, butt weld, flanged, threaded.

Operation: handwheel operated, gear operated, electric actuated, pneumatic actuated.