- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

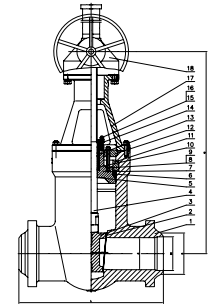

Pressure Seal Gate Valve

Middleeast valve is the leading Pressure seal gate valve suppliers in Qatar. A gate valve is a type of valve used to control the flow of fluid through a pipeline. It employs a gate or wedge-shaped disk that moves perpendicular to the flow of the fluid, either fully opening or fully closing the passage.

What is pressure seal gate valve?

It is a specialized type of gate valve designed to withstand high pressures and temperatures. It utilizes a unique sealing mechanism that enhances its ability to maintain a tight seal even under extreme conditions.

The distinguishing feature of a pressure seal gate valve is its pressure seal bonnet design. Unlike conventional bolted bonnet gate valves, pressure seal gate valves feature a bonnet that is integrally connected to the body, creating a pressure-tight seal. This design eliminates the need for external bolts and gaskets, reducing the risk of leakage.

Pressure seal gate valves are specifically engineered for applications involving high pressures and temperatures, such as steam pipelines, power plants, and refining processes. They excel in environments where safety and reliability are paramount, offering dependable sealing performance even in harsh operating conditions.

The key features of pressure seal gate valves include their robust construction, superior sealing capability, and ability to withstand extreme pressure differentials. They are often constructed from high-strength materials such as forged steel or alloy steel, ensuring durability and longevity. Pressure seal gate valves are also available in various configurations, including rising stem and non-rising stem designs, to suit different installation requirements.

Pressure seal gate valve suppliers in Qatar plays vital roles in fluid control systems across a wide range of industries. While standard gate valves offer versatility and reliability in general applications, pressure seal gate valves are specifically engineered to meet the demands of high-pressure and high-temperature environments.

Industries:

Power Generation Plants

Oil and Gas Industry

Chemical and Petrochemical Industry

Mining Industry

Pulp and paper Industry

Marine Industry

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel, Gear operated , Electric actuated and Pneumatic Actuated

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded