- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Pressure Seal Check Valve

Middleeast valve is the top most and well know Pressure seal check valve supplier in Kuwait. We supply to UAE, Qatar, Bahrain, Lebanon and Cyprus. A pressure seal check valve is a type of check valve that uses a pressure seal to prevent backflow. The valve features a pressure-assisted seal that is designed to close tightly against the valve seat, preventing backflow and ensuring a tight seal. These valves are typically used in high-pressure and high-temperature applications, such as power plants and chemical processing plants. They are also commonly used in pipelines and other fluid systems where a tight seal is required to prevent leakage.

Middleeast valve is the largest and fast-growing Pressure seal check valve supplier in Kuwait. While manufacturing, we keep in mind the industrial standards and maintain the quality standards of the valves.

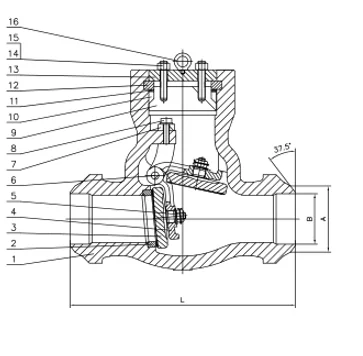

Parts

Body

Disc

Seat

Hinge

Spring

Cover

Yoke

Pressure Seal

Advantages

These valves are designed to withstand high pressure and temperature conditions, making them ideal for use in power plants, chemical processing plants, and other high-pressure applications.

The pressure-assisted seal on these valves provides a tight seal against the valve seat, preventing backflow and ensuring that there is no leakage.

These valves have relatively simple designs, with few internal moving parts, which makes them relatively easy to maintain and repair.

They are typically made of high-quality materials such as stainless steel or alloy, which makes them durable and resistant to wear and tear.

These valves typically have a compact design, which allows them to be easily installed in pipelines and other fluid systems.

These valves are known for their reliability, as they are designed to operate with a high degree of accuracy and repeatability.

The pressure seal design allows for low opening and closing torque, reducing the stress on the actuator.

They can be actuated by a simple pneumatic or hydraulic actuator, making them easy to control and automate.

Due to the pressure seal design, these valves typically have a longer life span than traditional check valves.

Industries

Power Generation Plants

Oil and Gas Industry

Chemical Processing Industry

Paper and Pulp Industry

Marine Industry

Applications

These valves are used to control the flow of steam in power plants, industrial boilers, and other high-pressure steam systems.

These valves are used to control the flow of water in pipelines, treatment plants, and other water systems.

They are used to control the flow of crude oil, natural gas, and other fluids in pipelines and processing plants.

These valves are used to control the flow of corrosive and hazardous chemicals in chemical processing plants.

These valves are used to control the flow of liquids and gases in sterile environments in pharmaceutical manufacturing.

They are used to control the flow of fluids in waste water treatment plants.

These valves are used to control the flow of feedwater in boilers, and other high-pressure systems.

Pressure seal check valves are used to control the flow of water in fire protection systems.

These valves are used to control the flow of compressed air in pneumatic systems.

Description

Available materials: Cast iron, Ductile iron, WCB, LCC, CF8M, SS304, SS316, SS316L, ASTM A105N, ASTM A182Gr-F304, ASTM A182Gr-F316

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: 1/2” to 40”

Ends: Flanged, Wafer, lug, Threaded, Buttweld, Socket weld