- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

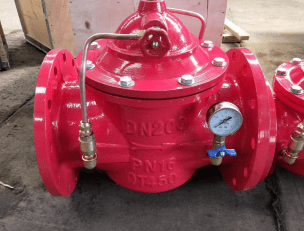

Pressure relief and sustaining valve supplier in Qatar- Safe and Steady Flow Management

Middleeast is a renowned and fast-growing Pressure relief and sustaining valve supplier in Qatar. It is a safety device that is designed to automatically open and release pressure when a predetermined pressure limit is exceeded.

Difference Between Pressure Relief Valve and Sustaining Valve:

Though pressure relief as well as sustaining valves are utilized for the regulation of pressure, they are utilized for different purposes-

1)Pressure Relief Valve (PRV): Pressure relief valve is utilized to safeguard a system against a higher pressure. On the rise of pressure above a given level, the valve opens up to let out the excess fluid to avert system damage. It is actually used as a safeguard against overpressure conditions.

2)Pressure Sustaining Valve (PSV): A pressure sustaining valve, by contrast, provides a minimum level of pressure within the system. As the pressure decreases below the established limit, the valve opens to admit more fluid into the system to sustain the pressure continually for best operation.

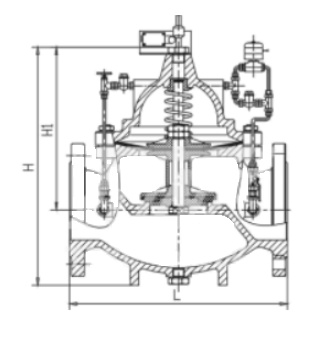

Key Parts:

1)Valve Body: The covering which contains the valve mechanism.

2)Spring: Regulates the valve opening according to pressure.

3)Seat and Disc: The ones that open and close to relieve pressure.

4)Inlet and Outlet Ports: Offer routes for the fluid to flow into and out of the valve.

Benefits:

1)Avoid System Overload

2)Lessen risk of catastrophic system failure

3)Automatic Operation

4)Economical Protection

Applications:

1)Oil and Gas Industry

2)Power generation Plants

3)Chemical and petrochemical Industry