- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

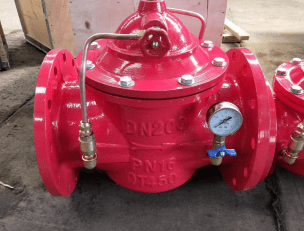

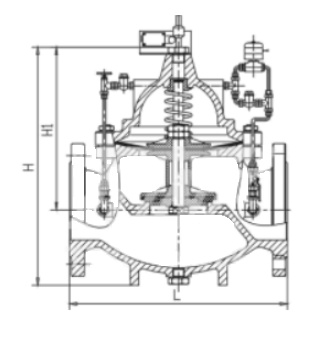

Pressure Relief and Sustaining Valve

Middleeast is a renowned and fast-growing pressure relief and sustaining valve supplier in Qatar. We also supply to major cities like Mesaieed, Doha, Ras Laffan and Al Khor. A pressure relief valve is a safety device that is designed to automatically open and release pressure when a predetermined pressure limit is exceeded. This is done to prevent damage to equipment or injury to personnel. A sustaining valve, also known as a pressure regulating valve, is used to maintain a consistent pressure in a system. It is typically used in applications where the inlet pressure is not stable and needs to be regulated. The valve automatically adjusts to changes in inlet pressure to maintain a constant outlet pressure. Middleeast is a top pressure relief and sustaining valve supplier in Qatar. While manufacturing, we keep in mind the industrial standards and maintain the quality standards of the valves.

Parts

A pressure relief valve typically consists of the following parts:

Body

Spring

Disc

Stem

A sustaining valve typically consists of the following parts:

Body

Inlet and outlet connections

Diaphragm or Piston

Stem

Bonnet

Advantages

The pressure relief valve is a critical safety device that prevents equipment damage and injury to personnel by automatically releasing pressure when it exceeds a predetermined limit.

Pressure relief valves are designed to be reliable and to operate automatically when needed.

Most pressure relief valves are designed for easy maintenance, making it simple to test and adjust the valve as needed.

The advantages of a sustaining valve include:

A sustaining valve helps to maintain a consistent pressure in a system, which can improve the performance of the equipment and prolong the life of the components.

By maintaining a consistent pressure, a sustaining valve can help reduce the energy consumption of equipment and machinery.

A sustaining valve can help to reduce the need for additional equipment, such as pressure tanks and pumps, which can save on costs.

A sustaining valve can be adjusted to maintain different pressure settings, making it suitable for a wide range of applications.

Industries

Oil and Gas Industry

Power generation Plants

Pharmaceutical Industry

Food and Beverage Industry

Chemical and petrochemical Industry

Applications

These valves are used in many industrial applications to protect equipment and personnel from overpressure. They are commonly used in boilers, steam systems, tanks, and process vessels.

They are used as a critical component of safety systems in many industrial applications. They are used to prevent equipment damage and injury to personnel by automatically releasing pressure when it exceeds a predetermined limit.

They are commonly used in steam systems to protect boilers and other equipment from overpressure. They are also used to release excess steam to the atmosphere when the pressure in the system exceeds the maximum allowed.

Are used in compressed air systems to protect compressors and other equipment from overpressure. They are also used to release excess compressed air to the atmosphere when the pressure in the system exceeds the maximum allowed.

They are used in gas systems to protect equipment and personnel from overpressure. They are commonly used in pipelines, storage tanks, and process vessels.

Sustaining valves are used in many industrial applications to regulate the pressure in process vessels, tanks, pipelines, and other equipment. They are used to maintain a consistent pressure in the system, which can improve the performance of the equipment and prolong the life of the components.

These valves are used in chemical process to protect equipment and personnel from overpressure. Sustaining valves are also used to regulate the pressure in process vessels and pipelines.

They are also used in flow control applications, where consistent flow rate is required.