- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

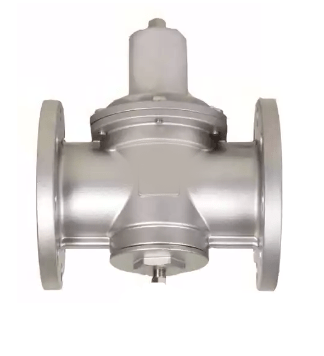

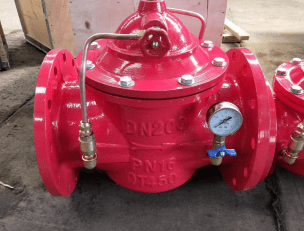

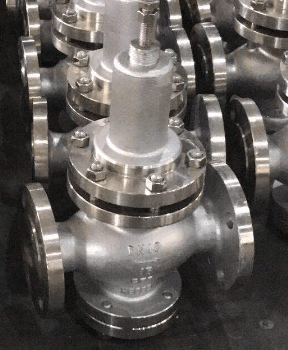

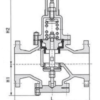

Pressure reducing Valve in UAE: Optimize System Pressure with Precision

Middleeast valve is famous for Pressure Reducing Valve in UAE. It is a valve that maintains a specific, predetermined pressure downstream of the valve, regardless of variations in upstream pressure. It acts as a barrier between the high-pressure source and the system or equipment that requires lower pressure, ensuring that the pressure remains within safe operating limits.

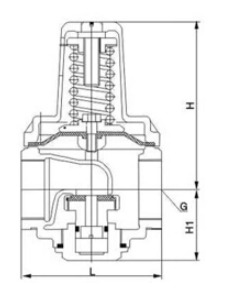

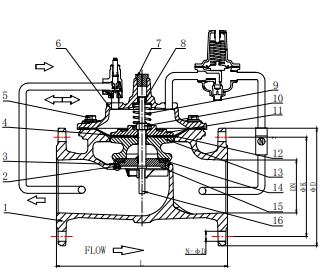

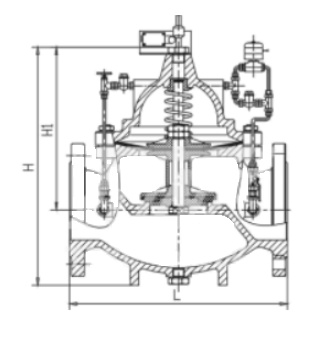

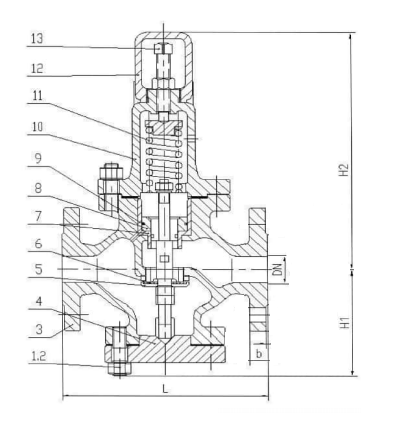

Key Parts of Pressure Reducing Valve:

1)Valve Body: This is the part of the pressure-reducing valve that houses the internal mechanism.

2)Diaphragm and spring: control balance and pressure setting

3)Disc or Seat: Control fluid flow with disc and seat.

4)Adjusting Screw: The pressure at the outlet is controlled by an adjusting screw.

Types:

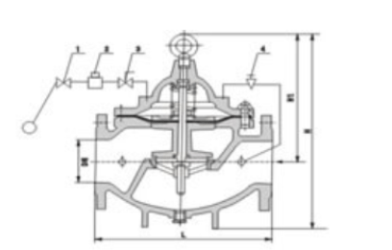

1)Direct acting pressure reducing valve

2)Pilot operated pressure reducing valve

3)Pressure-sustaining pressure reducing valve

Advantages of Using PRV:

1)Saves downstream equipment

2)Keeps pressure levels constant

3)Cost-effective and energy-efficient

4)Decreases maintenance requirements

Industries:

1)Oil and Gas Industry

2)Power Generation Plants

3)Chemical Industry

4)Water Treatment Plants

5)Plumbing and Irrigation Industry

6)Automotive Industry

7)Marine and offshore Industry

8)Aerospace Industry

9)Pulp and Paper Industry

10)Mining Industry

Description:

Body Material: Cast Iron, Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9) , Ductile Iron, Stainless Steel [ SS316 , SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3,F55, F91 ]

Class: 150 – 800, PN10 TO PN100

Size: 1/2” – 24”

Ends: Butt welded, Socket welded, Threaded, Flanged.