- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

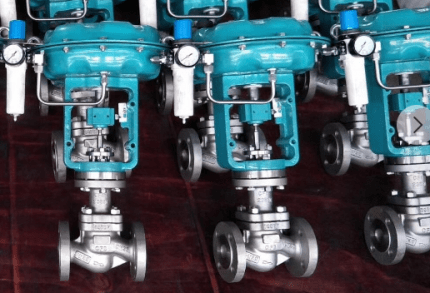

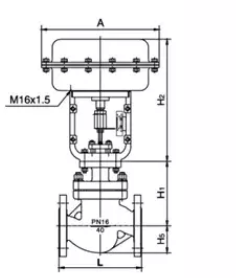

Pneumatic Single Seat Globe Control Valve

Middleeast is the largest and most famous pneumatic single seat globe control valve supplier in Iran. We supply to Tehran, Isfahan, Tabriz and Ahvaz. A pneumatic single seat globe control valve is a type of control valve that uses compressed air as the actuator to move a globe-shaped valve element within a valve body. This valve is designed for controlling the flow of fluid in a pipeline and can be used in a variety of applications such as process control, HVAC, and industrial automation. The valve’s single seat design allows for precise control of the flow rate and can be used to control the flow of liquids, gases, and steam. Pneumatic actuators are preferred in hazardous and explosive environments, as they are not electrical and do not produce sparks.

Middleeast is the greatest penumatic single-seat control valve supplier in Iran. While manufacturing, we keep in mind the industrial standards and maintain the quality standards of the valves.

Parts

- Valve body

- Globe v Pneumatic actuated flanged butterfly valve

- Stem

- Actuator

- Pneumatic connection

- Positioner

- Limit switches

- Gasket and seals

- Handwheel or other manual override

Advantages

- The single seat design of the valve allows for precise control of the flow rate, making it ideal for applications where accurate flow control is crucial.

- Pneumatic actuators can be easily controlled by a variety of control devices, such as pneumatic controllers, electric-pneumatic transducers, and programmable logic controllers (PLCs), which allows for flexibility in the control system.

- They do not produce sparks, making them suitable for use in hazardous and explosive environments.

- Pneumatic single seat globe control valves are typically made of robust materials, such as stainless steel and brass, and are designed to withstand high pressure and temperature, which makes them highly durable.

- These valves are relatively simple in design, which makes them easy to maintain and repair.

- They are relatively inexpensive and are less complex than other types of actuators, which makes them a cost-effective option for many industrial and commercial applications.

Industries

- Power Generation Plants

- Water Treatment

- Pharmaceuticals & Biotechnology

- Food and Beverage

Application

- These valves can be used to control the flow rate of liquids, gases, and steam in pipelines, ensuring that the flow is maintained at a consistent level.

- They can be used to control the pressure of fluids in a pipeline, ensuring that it remains within a safe range.

- They can be used to control the temperature of fluids in a pipeline, ensuring that it remains within a safe range.

- These valves are used to control the level of fluids in tanks or vessels, ensuring that it remains within a safe range.

- They can be used as on-off valves to open or close the flow of fluids in a pipeline.

- They are used as safety shut-off valves, which automatically close in the event of an emergency, to prevent damage or injury.

- They can be used to proportionally control the flow of fluids in a pipeline, which allows for more precise flow control and better process stability.

- They are used to control the flow of fluids in order to mix and blend different fluids in a pipeline.

- They can be used to divert the flow of fluids from one pipeline to another.

- They are used to regulate the flow of fluids in order to maintain a constant flow rate, pressure or temperature in a pipeline.