- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

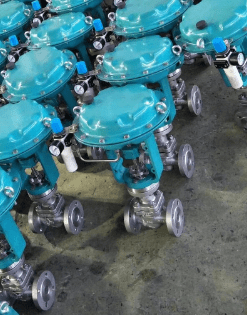

Pneumatic Double Seat Control Valve

Middleeast is a leading pneumatic double seat control valve supplier in Sharjah. We also supply to Oman, Qatar, Saudi Arabia, Syria. A control valve is a device used to regulate the flow of fluids (such as liquids, gases, or slurries) in a piping system. It is typically used in industrial process control applications to adjust the flow rate, pressure, temperature, or other process variable. A pneumatic double seat control valve is a type of valve that uses compressed air to control the flow of a fluid through two separate seats, which can be adjusted to regulate the flow rate. The valve typically has a pneumatic actuator that moves the seats and controls the flow through the valve. This type of valve is commonly used in industrial and process control applications, such as in power plants, oil refineries, and chemical plants, where precise control of flow is important. Middleeast is the greatest penumatic double-seat control valve supplier in Sharjah. While manufacturing, we keep in mind the industrial standards and maintain the quality standards of the valves.

Parts

- Valve body

- Valve plug

- Actuator

- Pneumatic control signal

- Inlet and outlet seats

- Positioner

- Limit switches

- Accessories

Advantages

- The double seat design allows for precise control of flow, making it ideal for applications that require tight process control.

- These valves have relatively few moving parts, which means they require less maintenance than other types of valves.

- The pneumatic actuator allows for quick and precise control of the valve, which is useful in applications where fast response time is important.

- These valves are available in a wide range of sizes and materials, making them suitable for a variety of applications, including those in harsh environments.

- These valves are relatively inexpensive compared to other types of valves, making them a cost-effective option for many industrial applications.

Industries

- Chemical and petrochemical Industry

- Power Generation Plants

- Oil and gas Industry

- Pulp and Paper Industry

- Water treatment Industry

Applications

- These valves are used to regulate the flow of liquids, gases, and semi-solids in various process systems.

- Pneumatic double seat control valves can be used to maintain a constant pressure in a process system.

- These valves can be used to regulate the temperature of a process by controlling the flow of a coolant or heating fluid.

- Pneumatic double seat control valves can be used to control the level of a fluid in a tank or other container.

- These valves can be used to control the flow of different fluids in order to mix or blend them.

- These can be used to open or close a process line in order to start or stop the flow of a fluid.

- They can be used as a safety shut-off in emergency situations to prevent the release of hazardous fluids.

- They can be used to control the pressure drop across process systems to optimize performance.

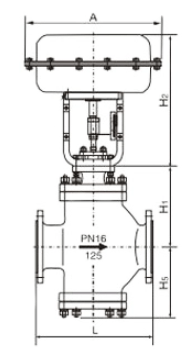

Description

- Available Materials: Ductile Iron, Cast iron, WCB, WCC, WC6, LCC, LCB, SS316, SS304, F51, F53, F55

- Class: 150 to 2500

- Nominal Pressure: PN10 to PN450

- Size: ½” to 24”

- Medium: Air, Water, Chemical, Steam, Oil

- Operations: Pneumatic Actuated