- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

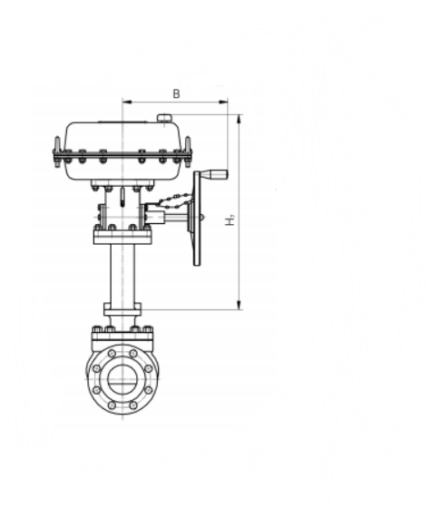

Pneumatic Cage Control Valve

Middleeast is the greatest pneumatic cage control valve supplier in Lebanon. A pneumatic cage control valve is a type of valve that uses compressed air to control the flow of fluid in a pipeline. The valve consists of a cage that surrounds a piston or diaphragm, which is used to open and close the valve by moving up and down in response to the pressure of the compressed air. Pneumatic cage control valves are typically used in industrial and commercial settings where precise control of fluid flow is required, and are often used in conjunction with other types of control valves or actuators.

Middleeast is a leading and renowned pneumatic cage control valve supplier in Lebanon. While manufacturing, we keep in mind the industrial standards and maintain the quality standards of the valves.

Parts:

- Valve body

- Cage

- Valve stem

- Actuator

- Air supply

- Seals

- Control signal

- Indicator

Advantages

- These valves are capable of precise control of fluid flow, which makes them well-suited for applications that require accurate flow control.

- They are relatively simple in design and have few moving parts, which makes them less likely to malfunction or fail.

- They are designed to withstand the pressures and temperatures of the fluid being controlled, and are often constructed from materials that are resistant to corrosion and wear.

- These valves require minimal maintenance, which makes them a cost-effective option for many industrial and commercial applications.

- Can be easily installed in a pipeline and can be integrated with other control valves or actuators to create a complete control system.

- Are relatively inexpensive compared to other types of control valves, which makes them a cost-effective option for many applications.

- They can be operated remotely, which eliminates the need for workers to be in close proximity to the valve while it is being operated, improving safety in the workplace.

- These valves come in a variety of designs, which makes them suitable for a wide range of applications and fluid types.

- Can respond quickly to changes in pressure, which makes them well-suited for applications that require fast and precise control of fluid flow.

Industries

- Oil and gas Industry

- Power Generation Plants

- Chemical Processing Industries

- Water treatment Pants

- Automotive Industries

- Marine Industries

Applications

- Pneumatic cage control valves are used to control the flow of fluid in pipelines, allowing for precise regulation of the flow rate.

- Can be used to control the pressure of a fluid in a pipeline, which is important for maintaining safe and efficient operation of the system.

- They can also be used to control the temperature of a fluid in a pipeline, which is important for maintaining safe and efficient operation of the system.

- These valves can be used to turn the flow of fluid on or off, which is important for maintaining safe and efficient operation of the system.

- These valves can be used as safety shut-off valves, which automatically close in the event of an emergency to prevent damage or injury.

- Can be used to control the flow of fluid in a bypass circuit, which allows for the diversion of fluid around a system or component.

- Pneumatic cage control valves can be used to control the flow of multiple fluids in a pipeline, which allows for mixing and blending of different fluids.

- These can be used to control the flow of fluids or gases in a dosing system, which allows for the precise addition of chemicals or other substances to a process.

- These valves are used to control the flow of fluids or gases in a sampling system, which allows for the collection of samples for analysis or testing.

- They are used in many industrial processes as a pneumatic actuator to open or close a valve.

Description

- Size: The size of the valve is also determined by the connection size, which can vary from small pipe size (1/4″ to 2″) to large pipe size (10″ and above).

- Body Material: Cast iron, Ductile iron, Carbon, Stainless steel, Bronze, Aluminum

- Ends: Flanged, butt weld, socket weld, threaded