- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

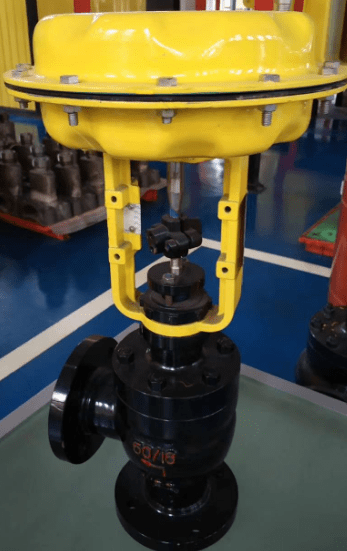

Pneumatic Angle Control Valve

Middleeast valve is the topmost Pneumatic angle control valve suppliers in Saudi Arabia. A control valve is a valve used to manage and direct the flow of a fluid by varying the size of the flow passage as directed by a signal from a controller. This process adjustment helps maintain the desired output of a system within certain parameters.

Pneumatic Angle Control Valve: A pneumatic angle control valve is a specific type of control valve operated by pneumatic actuators. It is designed with an angled body, typically 90 degrees, which helps in controlling the flow direction and providing better control characteristics for certain applications.

Pneumatic Angle Control Valve Working:

Signal Reception: The pneumatic actuator receives a control signal, usually 4-20 mA or 3-15 psi.

Actuation: Compressed air enters the actuator, creating pressure that moves a diaphragm or piston.

Valve Movement: The movement of the diaphragm or piston translates into linear or rotary motion, which adjusts the valve stem or plug position.

Flow Regulation: The change in the valve stem position alters the flow path and rate, thus controlling the process variable such as flow rate, pressure, or temperature.

Pneumatic Angle Control Valves function:

Efficient Flow Direction: The 90-degree angle design aids in efficient flow redirection, making them suitable for applications requiring sharp turns in the fluid path.

High Flow Capacity: Due to their design, they offer lower resistance to fluid flow, providing higher flow capacity compared to straight-through valves.

Fast Response: Pneumatic actuation allows for quick and precise adjustments, making these valves ideal for processes requiring rapid control responses.

Pneumatic angle control valve suppliers in Saudi Arabia play a pivotal role in industrial automation and process control. Their ability to precisely regulate fluid flow ensures the smooth operation of various systems, from chemical processing to water treatment.

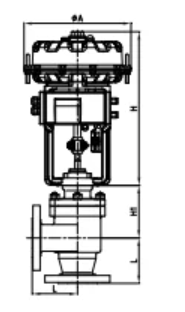

Description:

Available Materials: Ductile Iron Control Valve, Cast iron Control Valve(WCB, WCC, WC6) LCC, LCB, Stainless Steel (SS316, SS304), Super Duplex (F51, F53, F55)

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: Air, Water, Chemical, Steam, Oil

Operations: Electric actuated and Pneumatic actuated

Size: 1/2”- 24”

Ends: Flanged, butt weld, socket weld, threaded