- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

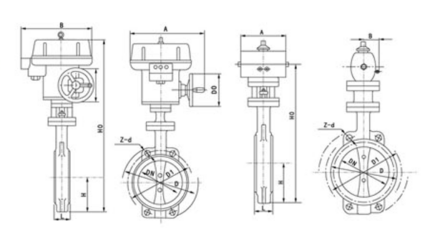

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

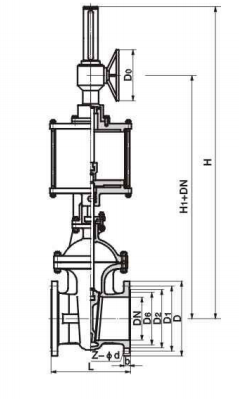

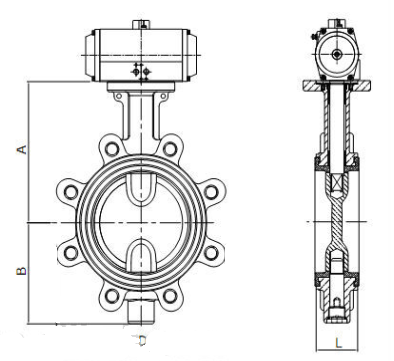

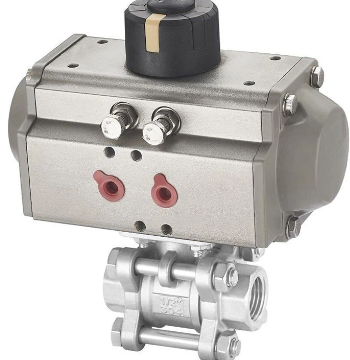

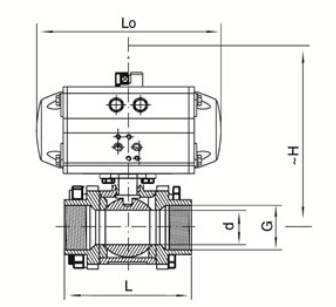

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

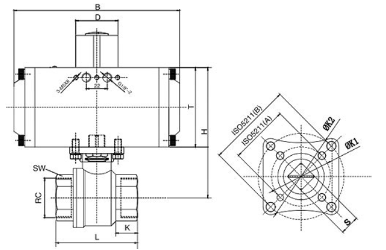

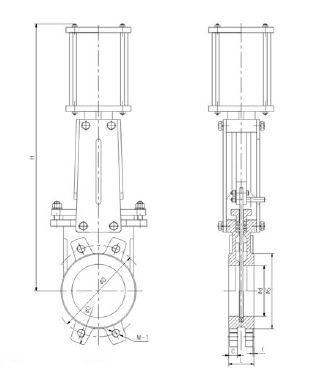

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

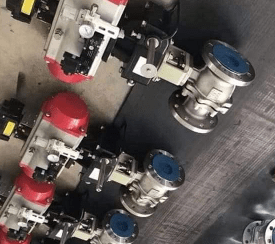

Pneumatic Actuated Valve Suppliers in UAE: Fast and Efficient Valve Automation

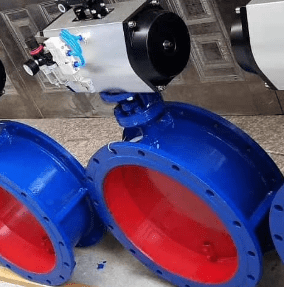

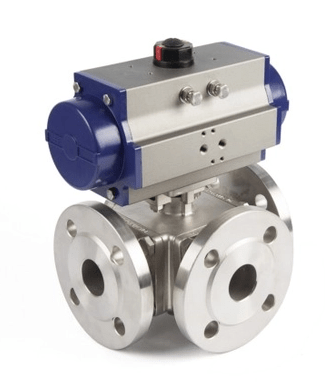

Middleeast valve is one of the best Pneumatic Actuated Valve Suppliers in UAE. It is a type of valve that uses compressed air or gas to control the opening and closing of the valve. The function of valve is to control the flow of a fluid by opening, closing, or modulating the valve’s position.

Working of Pneumatic Actuated Valve:

Compressed air powers the pneumatic actuator to drive the internal mechanism to open or close the valve. Air is utilized to open, close, or maintain the valve in place according to the type of actuator (single or double acting). This allows remote and automatic control in real-time.

Types:

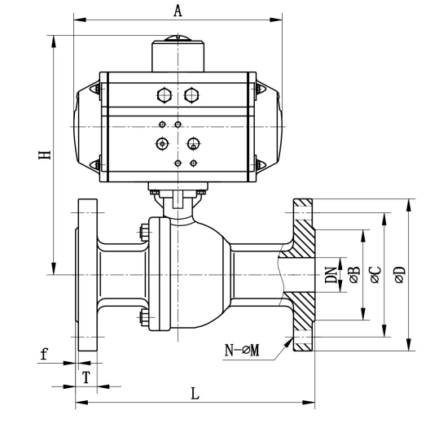

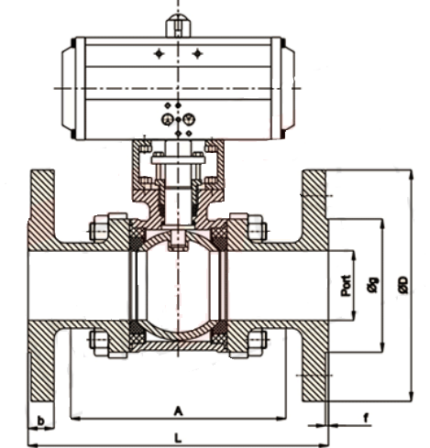

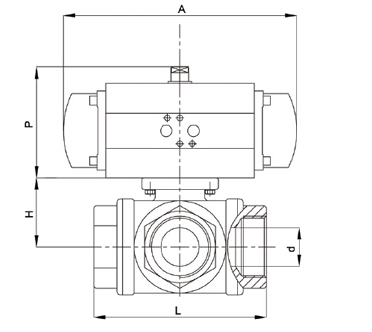

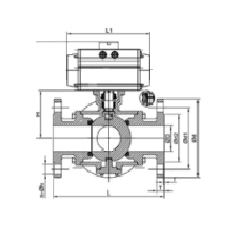

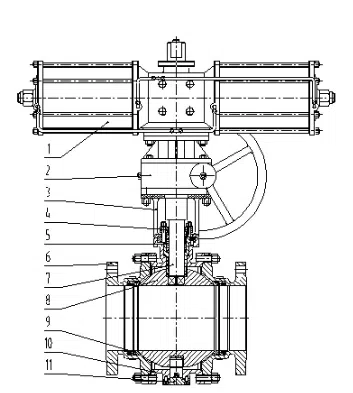

1)Pneumatic Actuated Ball valve

2)Pneumatic Actuated Gate valve

3)Pneumatic Actuated Butterfly valve

4)Pneumatic Actuated Knife Gate valve

Parts of Pneumatic Actuated Valve:

1)Valve Body: The main flow control element is located.

2)Pneumatic Actuator: Compressed air is utilized to develop mechanical motion.

3)Disc, Ball, or Gate: Control flow with stem and valve element.

4)Control Accessories: Limit switches, positioners, and solenoids.

Advantages of Using Pneumatic Actuated Valve:

1)Quick and dependable operation

2)Safe for hazardous conditions

3)Low power usage

4)Less downtime and maintenance

Description:

Available Material: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class: 150-2500, PN6-PN450

Ends: Flanged, Socket weld, Butt weld, Lug, Wafer, Threaded.

Operations: Pneumatic Actuated

Configuration of a Pneumatic Actuator:

1)Torque – 3 – 9000 nm

2)Operating pressure- 8 Bar

3)Port Connection-NPT1.4”

4)Mounting Base-ISO5211

5)Temperature–20°C – +80°C