- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

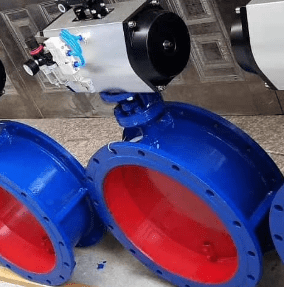

Pneumatic Actuated Flanged Butterfly Valve

A butterfly valve is a quarter-turn rotary valve that is used to control the flow of liquids and gases. It consists of a circular disc that is mounted on a shaft that passes through the center of the valve body. The disc rotates on an axis to open or close the flow through the valve. The valve is called a butterfly valve because the disc is shaped like a butterfly and rotates like the wings of a butterfly. A pneumatic actuated flanged butterfly valve is a type of valve that uses compressed air to open and close the valve. The disc is mounted on a shaft that is connected to a pneumatic actuator, which uses compressed air to rotate the disc. The valve has flanges on either side that are used to connect it to the pipe or ductwork in a fluid handling system. Pneumatic actuated butterfly valves are typically used in industrial applications where remote control or automation of the valve is desired.

Parts

- Valve Body

- Disc

- Shaft

- Pneumatic Actuator

- Flanges

- Gaskets

- Limit Switches

- Pilot Valve

Advantages

- Pneumatic actuation allows for the valve to be controlled remotely, which is useful in situations where manual operation is difficult or dangerous.

- These valves have a high flow capacity, making them suitable for use in large-scale industrial applications.

- These valves create a low pressure drop across the valve, which can help reduce energy costs in a fluid handling system.

- These valves are relatively easy to maintain and repair, which can help reduce downtime and costs.

- Pneumatic actuated butterfly valves have a compact design, making them a good choice for applications where space is limited.

- These valves are generally less expensive than other types of valves, such as globe valves or ball valves.

- They are made of durable materials and have a simple design, which makes them resistant to wear and tear, and easy to replace.

- Pneumatic actuated butterfly valves can be used in a wide range of applications and industries, such as chemical, oil and gas, mining, water treatment

Industry which uses them

- Oil and Gas industry

- Chemical Industry

- Power Generation Plants

- Water Treatment Plants

- Mining Industry

- Pharmaceutical Industry

- Food and Beverage Industry

- Marine Industry

- Pulp and Paper Industry

Applications

- Pneumatic actuated butterfly valves are commonly used to control the flow of liquids and gases in pipelines, ducts, and tanks.

- Pneumatic actuated butterfly valves can be used as shut-off valves in emergency situations, such as in case of a leak or other problem.

- They can be used to regulate the flow of fluids in a system, such as in HVAC systems or water treatment plants.

- They valves can be used to mix or divert different fluids in a system, such as in chemical processing plants.

- These valves are used as a bypass valve to redirect flow around an obstruction or to take a process offline for maintenance.

- Can be used for throttling, which is the process of adjusting the flow of a fluid to a specific rate.

- They can be used to control the pressure of fluids in a system, such as in power generation facilities.

- Are used to take samples of fluids in a system, such as in chemical processing plants or water treatment facilities.