- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

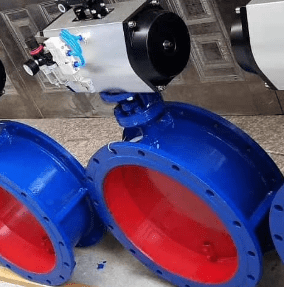

Pneumatic actuated butterfly valve suppliers in UAE

Middleeast valve is one of the best Pneumatic actuated butterfly valve suppliers in UAE. is a type of valve that uses compressed air or gas to control the opening and closing of the valve. It is a mechanism used to regulate the flow of a fluid (e.g., gas, liquid) through a pipe or tubing system.

Here is how it works:

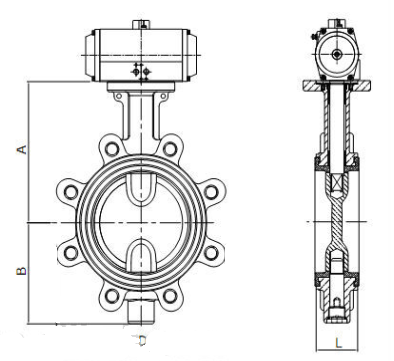

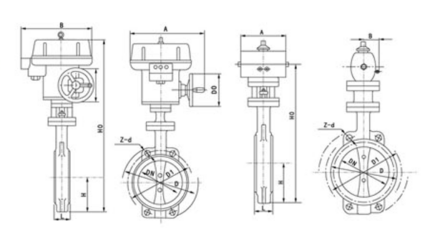

- Valve Structure: consists of a circular disc (the “butterfly”) that is mounted on a spindle or shaft in the center of the valve body.

- Actuator Attachment: The actuator, which is powered by compressed air or gas, is connected to the valve shaft. The actuator is responsible for moving the valve disc to control the flow.

- Controlled Rotation: When the actuator receives a signal to open or close the valve, it operates by allowing compressed air or gas to enter specific chambers within the actuator. The pressure and release of this air or gas cause the actuator to rotate the valve shaft.

Valve Operation:

- Opening the Valve: When the actuator receives a signal to open the valve, it pressurizes one side of the actuator, causing the actuator to rotate. This rotation is transferred to the valve shaft, causing the valve disc (butterfly) to rotate and open the valve.

- Closing the Valve: When the actuator receives a signal to close the valve, it pressurizes the other side of the actuator, which rotates the valve shaft in the opposite direction, causing the valve disc to close.

- Flow Regulation: The degree to which the valve opens or closes can be controlled by adjusting the amount of compressed air or gas provided to the actuator, allowing for precise regulation of the flow through the valve.

Advantages:

- Low maintenance

- Durable

- Reliable

- Available in different sizes

- Cost effective

- Can be used in various industries

Industries:

- Chemical Industry.

- Petroleum Industry.

- Mining Industry.

- Automobile Industry.

Description:

- Body material: Cast iron, Ductile iron, Stainless steel (SS316, SS304, CF8), Carbon steel, carbon steel, WCB, WCC, WC6, LCB, LCC, LF2, WC9, Duplex steel (F51, F53, 5A, 6A).

- Class: 150-300. PN10 –

- Size: 2”-72”.

- Connection type: Flanged, Lug type, Wafer type.

- Disc: CF8M, SS316L, CF8, Cast iron, Carbon steel, Ductile iron.

- Operation: pneumatic actuated.

Configuration of a Pneumatic Actuator:

- Torque – 3 – 9000 nm

- Operating pressure- 8 Bar

- Port Connection-NPT1.4”

- Mounting Base-ISO5211

- Temperature–20°C – +80°C