- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

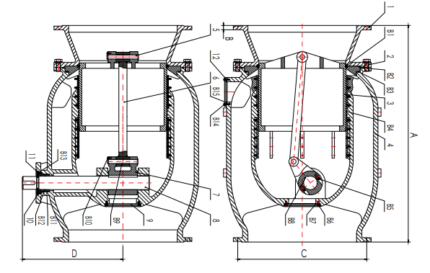

Plunger Valve Supplier in Saudi Arabia: Precision Flow Regulation with Durable Design

Middleeast valve is famous for Plunger Valve Supplier in Saudi Arabia. It is also known as a piston valve, is a type of valve used to control the flow of fluid (liquid or gas) through a pipe or tubing system. It consists of a cylindrical or conical plug, called a plunger or piston, which moves inside a matching cylindrical or conical housing or chamber. It can be lifted or lowered to open or close the valve, respectively, regulating the flow of fluid through it.

Working of Plunger Valve:

Plunger valves control the flow area by axially turning a cylindrical plunger within the valve body. The movement of the plunger restricts or opens up the flow stream, allowing easy regulation without sudden pressure drops or flow disturbances.

Key Components of Plunger Valve:

1)Valve Body: Durable housing that supports high pressure.

2)Plunger (Piston): Axial travel of the plunger (piston) changes flow.

3)Seat Rings: While closed, seat ring provides good seal.

4)Handwheels or Actuators: They permit manual or automatic operation.

5)Guiding System: Ensures smooth, vibration-free movement.

Advantages of Using Plunger Valve:

1)Excellent throttling performance

2)Reduced vibration and noise

3)High resistance to pressure shocks and cavitation

4)Minimal maintenance

Industries:

1)Water and Sewage Treatment

2)Chemical Processing Industry

3)Oil and gas production Industry

4)Power generation Plants

5)Pulp and paper Industry

6)Marine and shipping Industry

7)Mining and mineral processing Industry

Description:

Available material: Cast iron, Ductile iron, Cast steel (WCB).

Size- 4 Inch- 80 Inch

Pressure: PN 6-PN 63

Class: 150-300

Ends: Flanged

Operations: Handwheel