- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

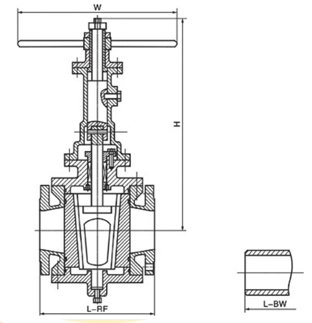

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

An Orbit Plug Valve is a type of valve designed for precise flow control in various industrial applications. It is recognized for its distinctive design that minimizes wear and tear, ensuring a longer service life. Unlike traditional plug valves, the Orbit Plug Valve features a rotating plug that lifts off its seat before turning, which significantly reduces friction and damage to the sealing surfaces.

The working principle of an Orbit Plug Valve involves a unique combination of rotational and linear motion. When the valve is operated:

1)Lifting Phase: The plug is lifted off from its seat to break any seals or adhesion caused by prolonged operation. This reduces the torque required to operate the valve.

2)Rotating Phase: Once lifted, the plug is rotated to open or close the flow path. Because the plug is not in contact with the seat during rotation, wear and friction are minimized.

3)Re-Seating Phase: After rotation, the plug is lowered back into its seat, providing a tight seal to prevent any leakage.

This design ensures smooth operation, minimal maintenance, and reliable performance over time. The primary function of an Orbit Plug Valve is to control the flow of fluids or gases in a pipeline. It can be used for full shutoff, throttling, or regulating the flow in various industrial processes, including oil and gas, chemical processing, and power generation. The valve’s design allows it to handle high-pressure, high-temperature applications with ease.

Features:

1)Low Operating Torque: The lifting action before rotation reduces friction, resulting in lower torque requirements.

2)Tight Sealing: The valve provides a reliable seal, reducing the risk of leakage even after prolonged use.

3)Durable Design: The lack of friction during operation minimizes wear, extending the valve’s service life.

4)Easy Maintenance: The unique design allows for easy inspection and maintenance without disassembling the valve from the pipeline.

Benefits:

1)Extended Service Life: Reduced friction and wear translate to longer operational life and fewer replacements.

2)Improved Safety: The tight seal and reliable operation ensure safe handling of hazardous fluids or gases.

3)Cost-Effective: Lower maintenance requirements and longer life reduce the overall cost of ownership.

4)Enhanced Performance: Precise flow control and minimal leakage contribute to more efficient system performance.

5)The Orbit Plug Valve is a trusted choice for industries requiring reliable, efficient, and durable flow control solutions.