- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

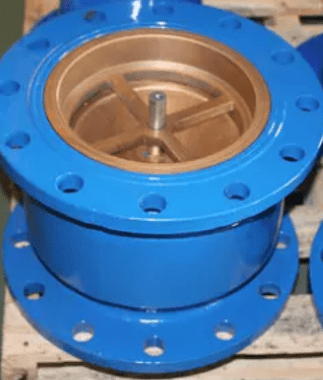

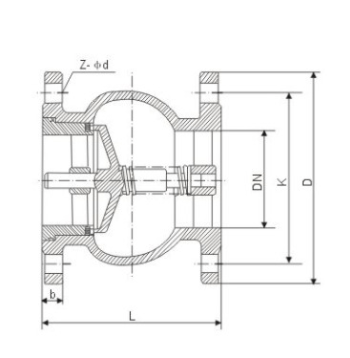

Non Slam Swing Check Valve

Middleeast valve is the foremost Non slam check valve manufacturers in Saudi Arabia. Swing check valves, commonly referred to as non-return or one-way valves, are a type of check valve that allows fluid to flow in one direction only. These valves are crucial in preventing backflow, thereby protecting equipment and maintaining system efficiency.

The primary function of a swing check valve is to permit the flow of fluid in one direction and prevent it from flowing in the reverse direction. This is achieved through a hinged disc or flap that swings open to allow forward flow and closes to block reverse flow. When the fluid flows in the desired direction, the pressure of the fluid pushes the disc away from the valve seat, allowing the fluid to pass through. If the flow reverses, the disc returns to its seated position, thus blocking the flow.

Working Principle:

Forward Flow: When the fluid flows in the intended direction, it exerts pressure on the disc, causing it to swing away from the valve seat. This opens the valve and allows the fluid to pass through with minimal resistance. The hinge mechanism ensures that the disc moves smoothly, providing a clear path for the fluid.

Backflow Prevention: When the fluid attempts to flow in the reverse direction, the pressure differential changes. The reverse flow exerts pressure on the downstream side of the disc, forcing it back towards the valve seat. The disc then closes tightly against the seat, preventing any backflow. The closure is aided by the force of gravity and sometimes by a spring mechanism, ensuring a prompt and secure seal.

Features:

Non slam swing check valves are designed to mitigate the common issue of water hammer, a phenomenon characterized by a sudden surge in pressure due to abrupt changes in flow velocity. This can cause significant damage to pipelines and equipment. Non-slam swing check valves incorporate several features to address this:

- Damping Mechanism: These valves often include a damping mechanism that slows the closing action of the disc, reducing the impact force and minimizing water hammer. This mechanism can be a dashpot, which is a cylinder filled with fluid that controls the disc’s movement.

- Silent Operation: The gradual and controlled closing action not only reduces water hammer but also ensures silent operation. This is particularly important in residential areas and facilities where noise reduction is crucial.

- Robust Construction: Non-slam swing check valves are typically constructed from durable materials like stainless steel, ductile iron, or bronze. This ensures longevity and reliability even under harsh operating conditions.

Applications:

Given their reliability and efficiency, non-slam swing check valves find applications in:

- Water Supply Systems

- Wastewater Treatment Plants

- Oil and Gas Industry

- Power Generation

Non slam check valve manufacturers in Saudi Arabia offering reliable backflow prevention and enhanced protection against water hammer. Their robust construction, efficient design, and ease of maintenance make them ideal for a wide range of applications across various industries.

Description:

- Body materials: Cast steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91] Duplex Steel (F51,F53,5A,4A,6A), Aluminium bronze, cast Iron and ductile Iron

- Class: 150 to 2500, PN10 to PN450

- Size: 1/2” to 48”

- End: Flanged, Socket weld butt weld, wafer, lug, threaded