- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

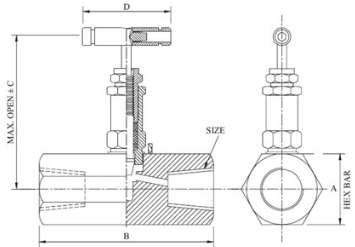

Needle Valve Suppliers in Saudi Arabia: Precision Control for Low Flow Applications

Middleeast valve is the well known for Needle valve suppliers in Saudi Arabia. It is a type of flow control valve used to regulate the flow of fluids in a precise and fine-tuned manner. Its design features a slender, tapered needle-like stem that fits into a conical seat.

It is one of the valves employed to control the flow of liquids or gases through pipelines with great accuracy. It has a long, tapering needle-shaped plunger which is seated, and fine regulation of the rate of flow can be achieved.

Main Components of a Needle Valve:

1)Valve Body – Outer casing that accommodates all internal parts.

2)Needle – A tapering and long plunger that regulates the flow of the medium.

3)Seat – The section of the valve against which the needle closes.

4)Stem – A piece of hardware that connects the actuator to the needle.

5)Handwheel or Actuator – Utilized to move the needle position to achieve accurate flow control.

Working Mechanism:

The operation of the needle valve involves moving the needle towards or from the seat. While in closure, needle closes the passage and prevent the fluid or gas flow. Upon opening valve, the needle slowly move from the seat, providing a controlled flow of the fluid through the valve. The mechanism allows delicate and precise flow control, which is suited for systems needing subtle adjustments.

Advantages of Needle Valve:

1)High Precision Flow Control: Suitable for applications involving fine control of fluids.

2)Leak proof Construction: Ensures tight fitment, eliminating leakage.

3)Long-lasting: Designed to withstand high pressure and high temperature setting.

4)Compact Design: Space saving and simple to install in space limited system.

Industries:

1)Oil and Gas

2)Chemical Processing

3)Water Treatment

Description:

Materials: SS316, SS316L, Duplex, Inconel 625, SS304, CF8, CF8M, F51, F53, F55,

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: 1/2” to 2”

Ends: Threaded, socket weld, butt weld

Operations: Hand wheel operated