- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

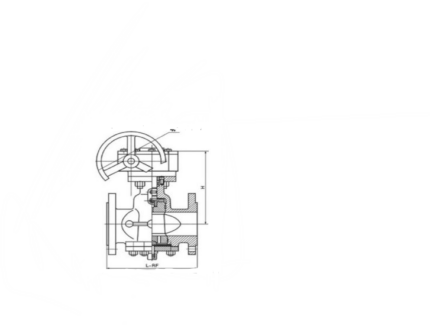

Lubricated Plug Valve

Middleeast valve is the leading Lubricated plug valve manufacturers in Saudi Arabia. It is a valve designed with a cylindrical or tapered plug that can be rotated inside the valve body to either allow or obstruct the flow of fluids (liquids or gases) through a pipeline.

[expander_maker id=”1″ more=”Read more” less=”Read less”]

It can isolate sections of a pipeline to facilitate maintenance or repair work. It can be used to control the rate of fluid flow by partially opening or closing the valve. The lubrication system helps reduce the friction between moving parts, making it easier to operate and extending the valve’s lifespan.

Here are the key components and steps in its operation:

Valve Body: The valve body is typically made of metal and contains a passage (bore) through which the fluid flows.

Plug: The plug is a cylindrical or tapered component that fits snugly inside the valve body’s bore. It can be rotated using a handle or actuator.

Flow Control: By turning the plug, the operator can either align the plug’s opening with the valve body’s bore (allowing flow) or position it perpendicular to the bore (blocking flow). The degree of rotation controls the flow rate.

Sealing: The lubricant on the plug’s surfaces helps create a tight seal when the plug is in the closed position, preventing fluid from leaking through the valve.

Advantages:

Protection of the seating against corrosion.

The high pressure ensures that there is no trapping of solids between valve body and plug.

Minimizing internal leakage.

The lubricant pressure prevents solids from entering the cavity in the plug.

Industries:

Petroleum Industry

Chemical Industry

Chemical Fertilizer Industry

Electric Power Industry

Waste Water Plants

Description:

Available materials: F22, CF8, CF3, CF3M, Ductile iron, WCB, WCC, WC9, WC6, Alloy 20, SS304, SS316,CF8M, SS316L, SS904L

Class: 150 to 2500, PN10 to PN450

Size:1/2” – 24”

End: Flanged, Socket weld, Butt weld, Screwed.

Operation:-Pneumatic Actuator, Electric Actuator Lever operator, Gear operator.

[/expander_maker]