- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

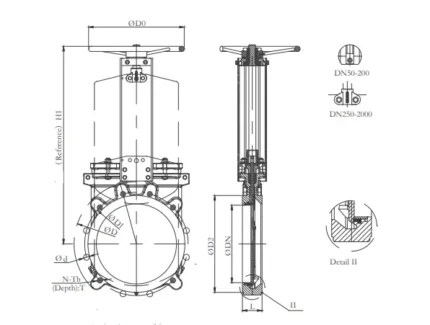

Knife Gate Valve Suppliers in UAE: Effective Isolation for Slurry and Solids

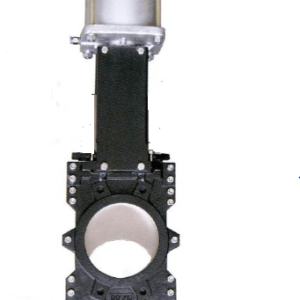

Middleeast valve is one of the largest Knife Gate Valve Suppliers in UAE. It is a type of industrial valve that is specifically designed for handling fluids containing suspended solids, slurries, or viscous materials.

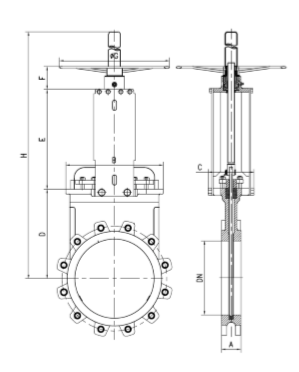

Key Components of a Knife Gate Valve:

1)Body: The primary body of the valve that contains all the pieces.

2)Gate: A flat, metal blade with sharp edges that moves up and down to either open or shut off the flow.

3)Stem: The element that connects the gate and the actuator so that the gate can move.

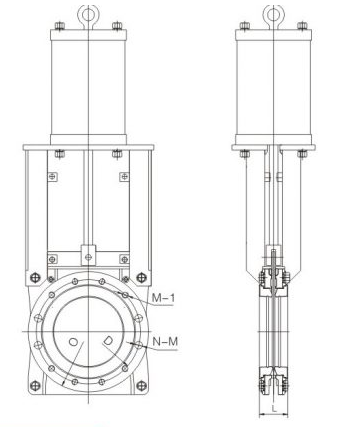

4)Actuator: A device that facilitates the movement of the gate (can be manual, pneumatic, or electric).

5)Sealing Mechanism: Provides that the valve ensures a tight closure when closed.

Working Mechanism:

Knife gate valve function through application of sharp edge gate that oscillate up and down within valve body. When the valve is in the closed position, the gate compress tightly against valve seat to seal it. The gate will cut through very thick, and therefore, is perfectly suited for abrasive and slurry fluids. Manual or actuator operation can be used on the valve, depending on the application.

Advantages:

1)Longevity: Knife gate valves are designed to withstand abrasive and slurry materials with no wear and tear.

2)Seal Confirmation: The sharp gate makes sealing sure even under extreme conditions.

3)Less Maintenance: The easy design and heavy-duty construction minimize the maintenance process.

4)Cost-Effective: Knife gate valves are an economical solution for managing rugged fluids in harsh industries.

Types of Knife Gate Valves:

1)Unidirectional Knife Gate Valve

2)Bidirectional Knife Gate Valve

3)Flanged Knife Gate Valve

4)Slurry Knife Gate Valve

5)Through Conduit Knife Gate Valve

Industries:

1)Wastewater treatment

2)Mining and mineral processing

3)Paper and pulp production

4)Chemical processing

Description:

Available materials: WCB, WC6, WCC, LCB, LCC, Cast iron, Ductile Iron, SS316, SS304

Size: 2″ to 80″

Class: 150 to 300

Nominal Pressure: PN6 to PN40

Operation: Handwheel, Electric and Pneumatic Actuated, Gear operated

Ends: Wafer, Lug, Flanged