- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

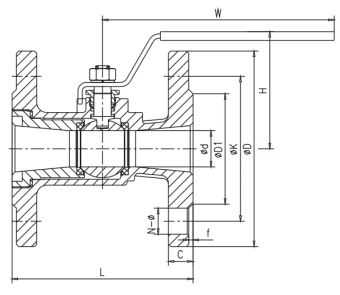

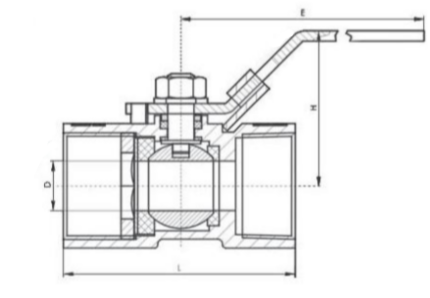

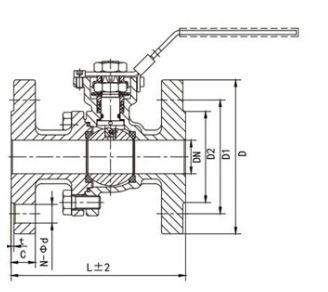

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

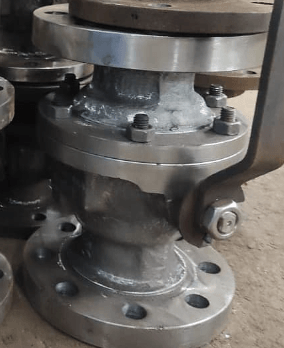

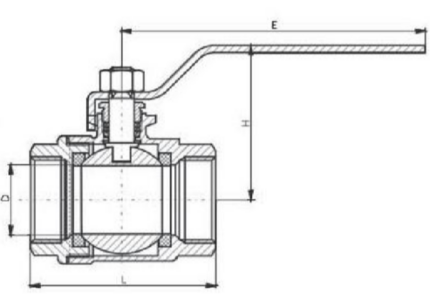

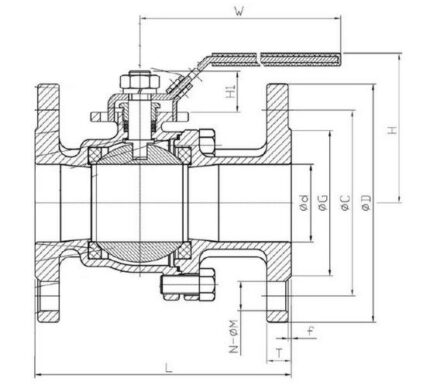

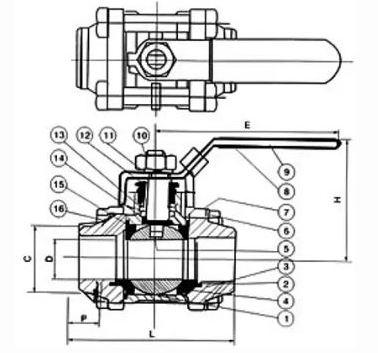

Middleeast valve is the greatest Investment casting ball valve supplier in Saudi Arabia. Investment casting ball valves are precision-engineered components used in fluid control systems. They are produced using the investment casting process, which involves creating a wax pattern, coating it with a ceramic material, and then melting the wax away to leave a detailed mold. Molten metal is poured into this mold to create the valve. This method allows for intricate designs and high accuracy in the finished product.

The primary function of an investment casting ball valve is to regulate the flow of liquids or gases through a piping system. The valve operates by rotating a ball with a hole (port) through its center. When the ball is turned to align the port with the pipeline, fluid flows through. When rotated 90 degrees, the ball blocks the flow, effectively stopping it.

Working:

1)Open Position: When the handle or actuator is turned, the ball inside the valve rotates so that the port aligns with the pipeline, allowing fluid to pass through.

2)Closed Position: Rotating the ball 90 degrees causes the solid side of the ball to block the flow, stopping the fluid movement.

3)Sealing: Ball valves typically use seats made of materials like Teflon to create a tight seal, ensuring no leakage when the valve is in the closed position.

4)Control: These valves can be operated manually, electrically, or pneumatically, providing various options for control depending on the application.

Features:

1)Precision Casting: The investment casting process ensures high dimensional accuracy and smooth surfaces, reducing the need for machining.

2)Material Versatility: Can be made from various metals, including stainless steel, brass, and other alloys, to suit different environmental conditions and applications.

Benefits

3)Enhanced Flow Control: Provides precise and reliable control of fluid flow, essential for maintaining system efficiency and safety.

4)Leak-Proof Operation: The tight sealing capability ensures zero leakage, which is critical in preventing wastage and ensuring safety in hazardous environments.

5)Cost-Effective Production: The investment casting process can reduce material waste and machining costs, making it a cost-effective option for producing high-quality valves.

6)Long Service Life: Durable construction and resistance to corrosion and wear result in a long service life, reducing maintenance and replacement costs.

7)Flexibility in Design: The ability to create complex shapes and fine details allows for customization to meet specific requirements and applications.

Investment casting ball valves are a vital component in modern fluid control systems, offering a blend of precision, reliability, and versatility. Their advanced manufacturing process and superior features make them an excellent choice for a wide range of industrial applications.