- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

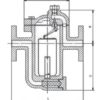

Middleeast Valve is the largest Inverted Bucket Steam Trap Supplier in Kuwait. An Inverted Bucket Steam Trap is a type of mechanical steam trap that is widely used in industrial applications to remove condensate, air, and non-condensable gases from steam systems. It operates based on the difference in density between steam and condensate, using an inverted bucket mechanism to open and close a valve, thereby allowing the discharge of unwanted condensate while retaining steam in the system.

The Inverted Bucket Steam Trap operates using the principle of buoyancy. It consists of an inverted bucket attached to a lever, which controls a valve. The trap is filled with condensate upon start-up, causing the bucket to sink and opening the valve. This allows the condensate to be discharged. When steam enters the trap, it fills the bucket, causing it to rise and close the valve. As steam condenses into water, the bucket loses buoyancy and sinks again, reopening the valve to discharge the condensate. This cycle repeats, effectively trapping steam and releasing condensate.

Features:

1)Simple Design: Fewer moving parts minimize the risk of mechanical failure and simplify maintenance.

2)Resistant to Water Hammer: The robust design can withstand water hammer and other system shocks.

3)Self-Priming: The trap automatically primes itself at start-up, ensuring immediate operation.

4)Air Handling: The trap efficiently handles air and non-condensable gases, preventing air binding.

The primary function of the Inverted Bucket Steam Trap is to remove condensate from steam systems without allowing live steam to escape. This ensures that the steam system operates efficiently, preventing water hammer, maintaining heating efficiency, and reducing energy loss. The trap also plays a critical role in removing air and non-condensable gases that can hinder the performance of the steam system.

Benefits:

1)Energy Efficiency: By preventing steam loss and ensuring proper condensate discharge, the trap contributes to overall energy savings.

2)Reliable Operation: The simple yet effective design ensures consistent performance with minimal maintenance.

3)Cost-Effective: The durability and longevity of the trap reduce the need for frequent replacements, lowering operational costs.

4)Improved System Performance: By maintaining the correct balance of steam and condensate, the trap helps optimize the performance of heat exchangers, radiators, and other steam-using equipment.

5)Safety: The robust design prevents failures that could lead to dangerous situations, such as water hammer or steam leaks.

Inverted Bucket Steam Trap is an essential component in steam systems, offering reliability, efficiency, and safety.