- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

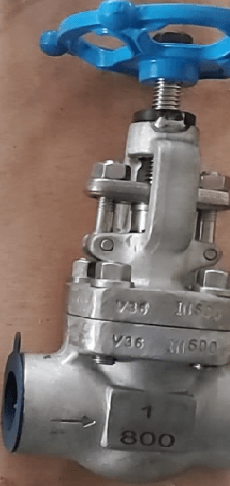

- Gate Valve

- Butterfly Valve

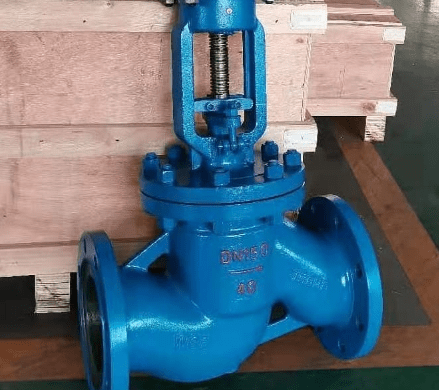

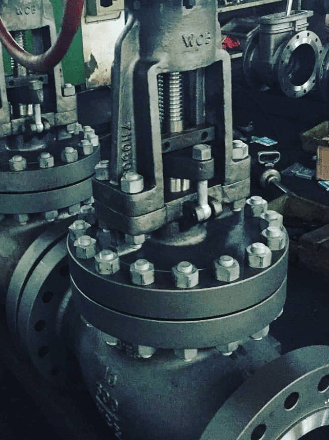

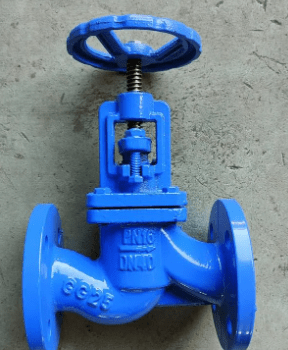

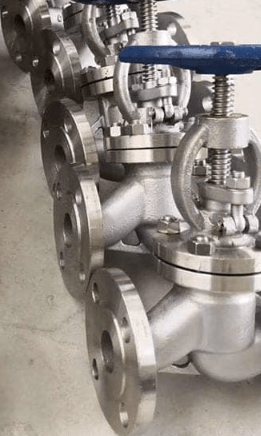

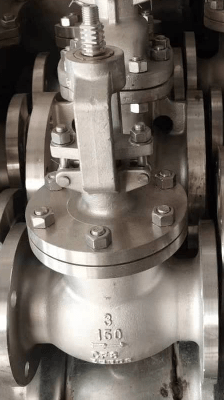

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Globe Valve

Online store with a wide selection of furniture and decor

Furniture is an invariable attribute of any room. It is they who give it the right atmosphere, making the space cozy and comfortable, creating favorable conditions for productive work or helping to relax after a hard day. More and more often, customers want to place an order in an online store, when you can sit down at the computer in your free time, arrange the furniture in the photo and calmly buy the furniture you like. The online store has a large catalog of furniture: both home and office furniture are available.

Furniture production is a modern form of art

Furniture manufacturers, as well as manufacturers of other home goods, are full of amazing offers: we often come across both standard mass-produced products and unique creations - furniture from professional craftsmen, which will be appreciated by true connoisseurs of beauty. We have selected for you the best models from modern craftsmen who managed to ingeniously combine elegance, quality and practicality in each product unit. Our assortment includes products from proven companies. Who for many years of continuous joint work did not give reason to doubt their reliability and honesty. All of them guarantee the high quality of their products, excellent operational characteristics, attractive appearance of the products, a long period of use of the furniture, as well as safety.