- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

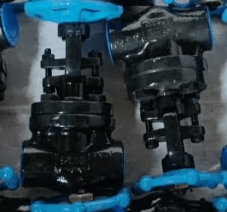

Forged Steel Gate Valve

Middleeast Valve is a famous Forged steel gate valve supplier in Dubai. Forged Steel Gate Valves are constructed with a bolted bonnet, an outside screw and yoke, a rising spindle, and a non-rising hand wheel. Forged Valves are made of high-quality forgings.

Forged Steel Gate Valves are also available for third-party inspection. F6 Face Seat & Disc are available for high pressure and temperature applications. Threaded End (BSP / NPT Female), Socket Weld End, Butt Weld End, Weld Neck End, and Flanged End Connection are all options for forged gate valves.

Definition of Forging

Forging is a metalworking process that involves shaping metal with localised compressive forces. There are three types of forging processes based on the temperature of the metal being worked with: cold forging, warm forging and hot forging.

Definition of Forged Steel:

Forged steel is a carbon and iron alloy that has been compressed under extreme pressure to create a very hard and strong substance. It has been used to make various materials for thousands of years. Specialized machines or hydraulic hammers are used in modern forged steel production. When it comes to understanding the benefits of forged steel, there are numerous factors to consider.

Industries that use Forged Steel Gate Valves:

Power industry

Petroleum industry

Oil & Gas industry

Chemical industry

Metallurgical industry

Applications of a Forged Steel Gate Valve:

Power Plants & Process Industries

Petrochemical Plants & Refineries

Fertilizers Plants

Cement & Steel Industries

Process & General Industries

Advantages of a Forged Steel Gate Valve:

The fluid resistance of the forging steel gate valve is low, and the medium brushes and erodes the sealing surface less.

Forged steel gate valves are suitable for small diameter lines with Class150 2500, an operating temperature of -29 425°C (carbon steel) or -29 500°C (stainless steel), and are used to shut off or switch on the medium in the pipeline.

Butt-welded forged steel gate valves are simple in shape, have a short face-to-face dimension, are easy to manufacture, and are widely used.

Because the gate is placed vertically in the valve body and the globe valve’s valve flap is placed horizontally in the valve body, the structure is shorter in length than the globe valve.

Industries

Gate valves are used in many industrial applications, including:

Oil and gas industry

Manufacturing

Automotive

Marine

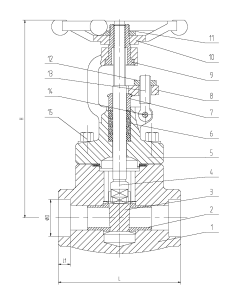

Description :

Middleeast Valve is the famous Forged steel gate valve supplier in Dubai offering an extensive range of valves in numerous sizes, styles and designs.

Class: 150 to 2500, PN25 to PN450

End: Buttweld, Flanged, Socketweld, Threaded

Operations: Hand Wheel, Gear operated, Electric actuated and Pneumatic Actuated

Material: A105, F11, F22, F51, F304, F304L, F316, F316, F91, LF2

Size: 1/2″ to 24″