- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

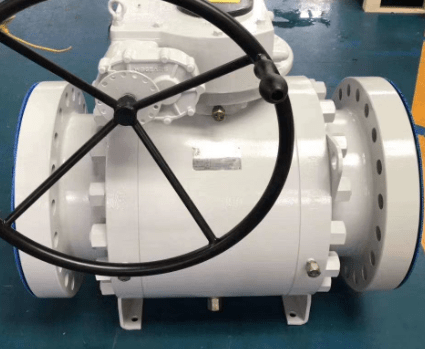

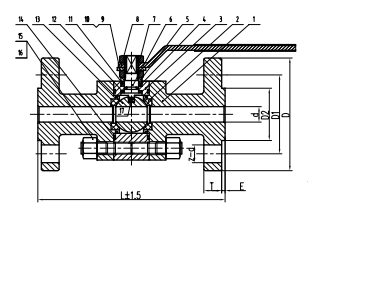

A Forged Floating Ball Valve is a type of ball valve where the ball is not fixed but “floats” between two seats. This valve is commonly used in industries to control the flow of fluids like gas, steam, and liquids. The body of the valve is typically made through forging, which enhances its mechanical properties, such as strength, durability, and resistance to high pressure and temperature.

Working of Forged Floating Ball Valve:

The working principle of a floating ball valve revolves around the movement of a ball inside the valve body. The ball has a bore through the middle, allowing the fluid to pass when aligned with the flow. When the valve handle is rotated, the ball turns, either allowing fluid to flow (open) or blocking the flow (closed). Since the ball is not fixed, it is pushed against the downstream seat by the pressure of the fluid, creating a tight seal that prevents leakage.

Function of Forged Floating Ball Valve:

The primary function of a forged floating ball valve is to start or stop the flow of a fluid. It provides a reliable shut-off in both on-off and throttling applications. These valves are ideal for handling various media, including chemicals, gases, and even slurries, and are commonly used in industries like oil and gas, petrochemicals, power generation, and water treatment.

Features of Forged Floating Ball Valve:

Forged Construction: The valve body is made through a forging process, which makes it stronger, more durable, and capable of withstanding high-pressure applications.

Floating Ball Design: The ball is free to move within the valve body, allowing it to create a tight seal against the downstream seat when the valve is closed, which helps in leak prevention.

High Performance: These valves are known for their excellent performance in high-pressure, high-temperature environments, making them suitable for demanding industrial applications.

Compact and Lightweight: Compared to other types of valves, forged floating ball valves tend to have a more compact and lightweight design, which makes them easier to install and maintain.

Simple Operation: The valve operates with a simple 90-degree turn of the handle or actuator, providing quick and easy on-off control.

Forged floating ball valves are a robust and efficient solution for controlling the flow of various types of media in industrial settings, offering reliability, durability, and ease of operation.