- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

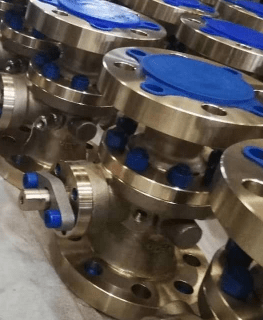

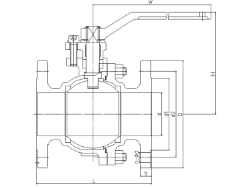

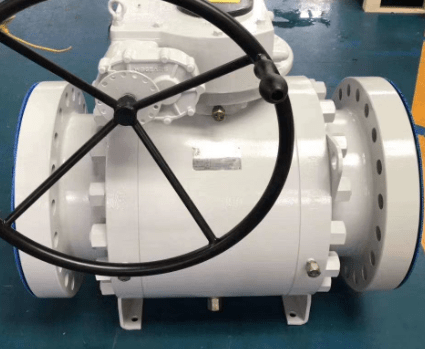

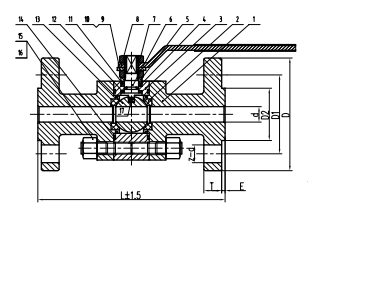

Floating ball valve

MiddleEast Valve is a reputed Floating ball valve suppliers in UAE. The valve comprises of a ball that can freely move or “float” inside the valve body and has a hole running through its center. The ball’s bore lines up with the pipeline when the valve is in the open position, allowing fluid to pass through. In contrast, when the ball is in the closed position, it spins to close the passage and stop fluid flow.These valves are crucial for controlling the flow of liquids and gases in industrial operations because they are made to withstand a range of pressures and temperatures and are especially good at creating a tight seal when closed.

[expander_maker id=”1″ more=”Read more” less=”Read less”]

The valves offers a dependable, low-torque sealing mechanism. The ball is forced against the downstream seat by the fluid pressure as the valve is closed, forming a tight seal and stopping all flow. They are perfect for quick shutoff and tight sealing applications, such those in the oil and gas sector, thanks to their design.

Advantages:

Simple Design

Low Friction

Quick Operation

Tight Sealing

Versatility

Bi-Directional

Applications:

Oil and Gas Industry

Chemical Industry

Water Treatment

Power Generation

Pipelines

Petrochemical Industry

Marine Industry

Description:

Body Materials: Cast Steel (WCB,WCC,WC6,WC9),Cast Iron, SS316, SS304, F22, F51, LF2, F304, F304L, F316, F316L.

Class: 150 to 2500

Ends: Flanged, Socket weld, Butt weld, Threaded

Size:1/4’’ to 48’’

Pressure: PN 10 – PN 450

Operation: lever operated, electric actuated, pneumatic actuated, gear operated

[/expander_maker]